Expansion in Construction Sector

The Methacrylic Acid Market is poised for growth, largely due to the expansion of the construction sector. Methacrylic acid is a key ingredient in the formulation of high-performance coatings and sealants used in construction applications. With the construction industry projected to grow at a CAGR of around 5% in the coming years, the demand for methacrylic acid is expected to rise correspondingly. This growth is driven by the increasing need for durable and weather-resistant materials in building projects. Furthermore, the trend towards sustainable construction practices may further enhance the appeal of methacrylic acid, as it can contribute to the development of eco-friendly construction materials. Thus, the expansion of the construction sector presents a significant opportunity for the Methacrylic Acid Market.

Rising Demand for Acrylic Polymers

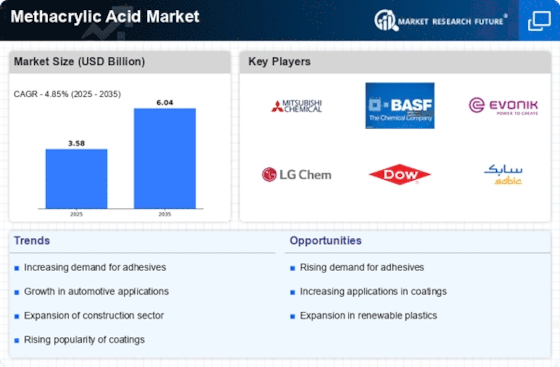

The Methacrylic Acid Market is significantly influenced by the rising demand for acrylic polymers across various applications. Acrylic polymers, which are derived from methacrylic acid, are widely used in paints, coatings, and adhesives due to their excellent clarity, durability, and weather resistance. The global market for acrylic polymers is anticipated to grow at a CAGR of approximately 6% over the next few years, which suggests a corresponding increase in the demand for methacrylic acid. This trend is particularly evident in the automotive and construction sectors, where high-performance coatings are essential. As industries continue to seek innovative solutions that enhance product performance, the Methacrylic Acid Market is likely to benefit from this growing demand for acrylic polymers.

Growing Focus on Sustainable Products

The Methacrylic Acid Market is increasingly influenced by the growing focus on sustainability and eco-friendly products. As consumers and industries alike prioritize environmentally responsible materials, the demand for methacrylic acid derived from renewable resources is likely to rise. This shift towards sustainability is evident in various sectors, including automotive, construction, and consumer goods, where companies are seeking to reduce their carbon footprint. The market for bio-based methacrylic acid is expected to expand, potentially leading to new product offerings and applications. This trend not only aligns with The Methacrylic Acid Industry to innovate and cater to the evolving preferences of consumers.

Increasing Applications in Automotive Industry

The Methacrylic Acid Market is experiencing a notable surge in demand due to its increasing applications in the automotive sector. Methacrylic acid is utilized in the production of various automotive components, including adhesives, coatings, and sealants. The automotive industry is projected to grow at a compound annual growth rate (CAGR) of approximately 4% over the next few years, which is likely to drive the demand for methacrylic acid. As manufacturers seek to enhance vehicle performance and durability, the incorporation of methacrylic acid in automotive applications appears to be a strategic choice. This trend indicates a robust potential for growth within the Methacrylic Acid Market, as automotive manufacturers increasingly prioritize high-performance materials that can withstand harsh environmental conditions.

Technological Innovations in Production Processes

The Methacrylic Acid Market is witnessing advancements in production technologies that could enhance efficiency and reduce costs. Innovations such as improved catalytic processes and the development of more sustainable production methods are emerging. These technological advancements may lead to higher yields and lower energy consumption, which are critical factors in the competitive landscape of the methacrylic acid market. As manufacturers adopt these new technologies, they may be able to offer methacrylic acid at more competitive prices, thereby expanding their market share. This trend indicates a potential shift in the Methacrylic Acid Market, as companies that embrace innovation are likely to gain a competitive edge in an increasingly demanding market.