Rising Demand in Electronics

The Micronized PTFE Market is experiencing a notable surge in demand from the electronics sector. This is primarily due to the material's excellent dielectric properties, which make it suitable for various electronic applications, including insulators and circuit boards. As the electronics industry continues to innovate, the need for high-performance materials like micronized PTFE is likely to increase. Recent estimates suggest that the electronics segment could account for a significant portion of the overall market share, potentially exceeding 25% by 2026. This trend indicates a robust growth trajectory for the Micronized PTFE Market, driven by advancements in technology and the increasing complexity of electronic devices.

Innovations in Manufacturing Techniques

Innovations in manufacturing techniques are significantly influencing the Micronized PTFE Market. Advances in processing technologies, such as improved grinding and classification methods, have enhanced the quality and consistency of micronized PTFE products. These innovations not only improve the performance characteristics of the material but also expand its applicability across various sectors, including automotive and aerospace. As manufacturers continue to refine their processes, the availability of high-quality micronized PTFE is expected to increase, potentially leading to a broader market reach. This trend suggests that the Micronized PTFE Market may witness a shift towards more specialized applications, driven by the demand for superior performance materials.

Expansion of Renewable Energy Technologies

The Micronized PTFE Market is witnessing growth due to the expansion of renewable energy technologies. Micronized PTFE Market is increasingly utilized in the production of components for solar panels and wind turbines, where its durability and resistance to environmental factors are paramount. As the world shifts towards sustainable energy solutions, the demand for high-performance materials like micronized PTFE is expected to rise. Market forecasts suggest that the renewable energy sector could account for a growing share of the Micronized PTFE Market, potentially reaching 10% by 2027. This trend highlights the material's adaptability and its importance in supporting the transition to cleaner energy sources.

Growth in the Chemical Processing Industry

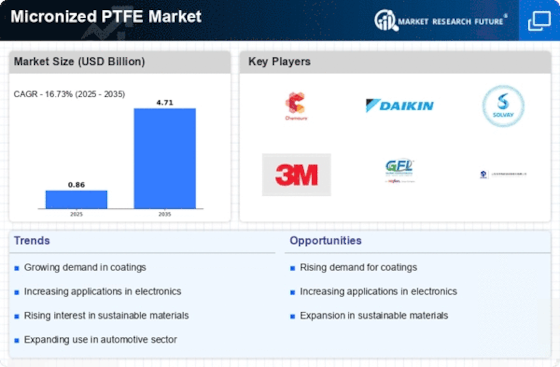

The Micronized PTFE Market is poised for growth, particularly within the chemical processing sector. Micronized PTFE Market is valued for its chemical resistance and thermal stability, making it an ideal choice for various applications, including seals, gaskets, and linings. As industries seek to enhance efficiency and reduce downtime, the adoption of micronized PTFE products is likely to rise. Market analysis indicates that the chemical processing segment may represent a substantial share of the Micronized PTFE Market, with projections suggesting a compound annual growth rate of around 6% over the next few years. This growth is indicative of the material's essential role in improving operational performance across diverse chemical applications.

Increasing Applications in the Food Industry

The Micronized PTFE Market is also benefiting from its increasing applications in the food industry. The material's non-stick properties and resistance to high temperatures make it an ideal choice for food processing equipment and packaging. As food safety regulations become more stringent, the demand for materials that can withstand harsh conditions while ensuring product integrity is likely to rise. Recent data indicates that the food sector could contribute significantly to the Micronized PTFE Market, with expectations of a growth rate of approximately 5% annually. This trend underscores the material's versatility and its critical role in enhancing food processing efficiency.