Technological Innovations

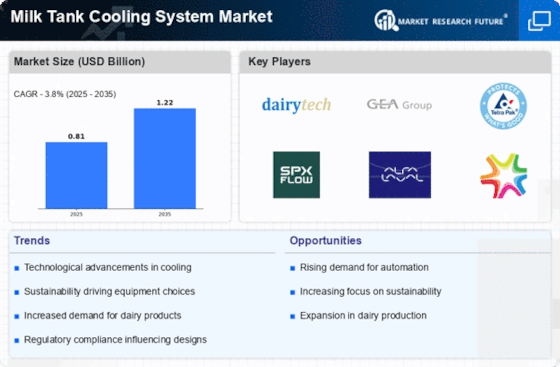

Technological advancements play a crucial role in shaping the Milk Tank Cooling System Market. Innovations such as smart cooling systems equipped with IoT capabilities are becoming increasingly prevalent. These systems allow for real-time monitoring of temperature and milk quality, thereby enhancing operational efficiency. The integration of automation in cooling processes not only reduces energy consumption but also minimizes human error, leading to improved product safety. Furthermore, the market has witnessed the introduction of energy-efficient cooling technologies that comply with environmental regulations. As a result, stakeholders are more inclined to adopt these advanced systems, which are projected to account for a significant share of the market. The ongoing evolution of technology in the Milk Tank Cooling System Market suggests a promising future for both manufacturers and consumers.

Increasing Dairy Production

The rising demand for dairy products is a primary driver for the Milk Tank Cooling System Market. As populations grow and dietary preferences shift towards dairy consumption, the need for efficient milk storage and cooling solutions becomes paramount. In recent years, dairy production has seen a notable increase, with reports indicating a rise of approximately 2.5% annually in milk output. This surge necessitates advanced cooling systems to maintain product quality and safety during storage and transportation. Consequently, dairy farmers and processors are investing in modern cooling technologies to ensure compliance with health standards and to extend the shelf life of milk products. The Milk Tank Cooling System Market is thus positioned to benefit from this upward trend in dairy production, as stakeholders seek reliable solutions to meet consumer demands.

Rising Awareness of Food Safety

The heightened awareness surrounding food safety is a significant driver for the Milk Tank Cooling System Market. Consumers are increasingly concerned about the quality and safety of dairy products, prompting stricter regulations and standards for milk storage and handling. This trend has led to a growing emphasis on the implementation of effective cooling systems to prevent spoilage and contamination. Regulatory bodies are enforcing guidelines that require dairy producers to maintain specific temperature ranges during storage and transportation. As a result, the demand for reliable milk cooling solutions is expected to rise. The Milk Tank Cooling System Market is likely to experience growth as dairy producers invest in systems that ensure compliance with these food safety standards, ultimately enhancing consumer trust in dairy products.

Sustainability and Energy Efficiency

Sustainability initiatives are increasingly influencing the Milk Tank Cooling System Market. As environmental concerns gain prominence, dairy producers are seeking energy-efficient cooling solutions that reduce their carbon footprint. The adoption of eco-friendly refrigerants and energy-saving technologies is becoming a priority for many stakeholders. Reports indicate that energy-efficient cooling systems can reduce operational costs by up to 30%, making them an attractive option for dairy farms and processing facilities. Additionally, the shift towards sustainable practices aligns with consumer preferences for environmentally responsible products. This trend is likely to drive investments in innovative cooling technologies that not only meet regulatory requirements but also contribute to sustainability goals. The Milk Tank Cooling System Market is thus poised for growth as it adapts to these evolving consumer and regulatory demands.

Expansion of Dairy Processing Facilities

The expansion of dairy processing facilities is a notable driver for the Milk Tank Cooling System Market. As the dairy sector continues to grow, there is a corresponding increase in the establishment of new processing plants aimed at meeting rising consumer demand. This expansion necessitates the installation of advanced milk cooling systems to ensure efficient operations and product quality. Recent data suggests that the number of dairy processing facilities has increased by approximately 5% annually, reflecting the industry's robust growth trajectory. Consequently, the demand for reliable and efficient cooling solutions is expected to rise in tandem with this expansion. The Milk Tank Cooling System Market stands to benefit from this trend, as processors seek to enhance their capabilities and maintain competitive advantages in a rapidly evolving market.