Technological Advancements

Technological advancements play a crucial role in shaping the Global Modified Epoxy Resins Market Industry. Innovations in resin formulations and processing techniques enhance the performance characteristics of modified epoxy resins, making them more appealing to various industries. For instance, the development of bio-based epoxy resins is gaining traction, aligning with global sustainability goals. These advancements not only improve product performance but also expand application areas, potentially increasing market penetration. As the industry evolves, the anticipated compound annual growth rate of 5.3% from 2025 to 2035 suggests a robust future for modified epoxy resins driven by ongoing technological progress.

Growth in Construction Activities

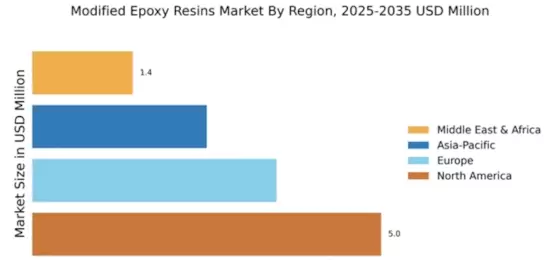

The Global Modified Epoxy Resins Market Industry benefits from the expansion of construction activities worldwide. Modified epoxy resins are favored for their superior adhesion, chemical resistance, and durability, making them ideal for various applications such as flooring, coatings, and adhesives. As urbanization accelerates and infrastructure projects increase, the demand for these resins is anticipated to rise. The construction sector's growth is expected to propel the market, with projections indicating a market value of 83.8 USD Million by 2035. This growth could be further supported by government initiatives aimed at enhancing infrastructure, thereby boosting the modified epoxy resins market.

Increasing Demand for Electronics

The Global Modified Epoxy Resins Market Industry is witnessing a surge in demand from the electronics sector, where these resins are utilized for encapsulation and insulation applications. The growing trend towards miniaturization and the need for reliable materials in electronic devices drive the adoption of modified epoxy resins. As consumer electronics continue to evolve, the market is likely to see increased utilization of these materials. This trend is expected to contribute to the overall market growth, with projections indicating a significant increase in market value as the electronics industry expands and seeks high-performance materials.

Rising Demand in Automotive Sector

The Global Modified Epoxy Resins Market Industry experiences a notable surge in demand from the automotive sector, driven by the need for lightweight and durable materials. Modified epoxy resins are increasingly utilized in vehicle components, enhancing performance and fuel efficiency. As automotive manufacturers focus on sustainability and reducing emissions, the adoption of these resins is likely to grow. In 2024, the market is projected to reach 47.5 USD Million, reflecting the automotive industry's shift towards advanced materials. This trend is expected to continue, potentially contributing to the overall market growth as the automotive sector evolves.

Environmental Regulations and Sustainability

The Global Modified Epoxy Resins Market Industry is influenced by stringent environmental regulations and a growing emphasis on sustainability. Manufacturers are increasingly required to adopt eco-friendly practices, leading to a shift towards modified epoxy resins that meet regulatory standards. This shift not only addresses environmental concerns but also aligns with consumer preferences for sustainable products. As companies innovate to develop greener formulations, the market is likely to expand. The anticipated growth in market value, alongside the increasing focus on sustainability, suggests a promising future for modified epoxy resins as industries adapt to evolving environmental standards.