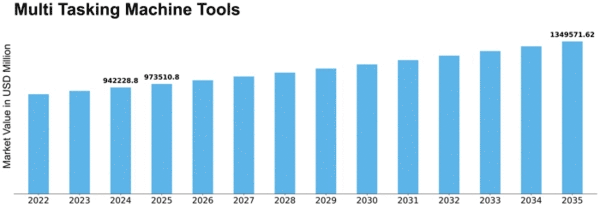

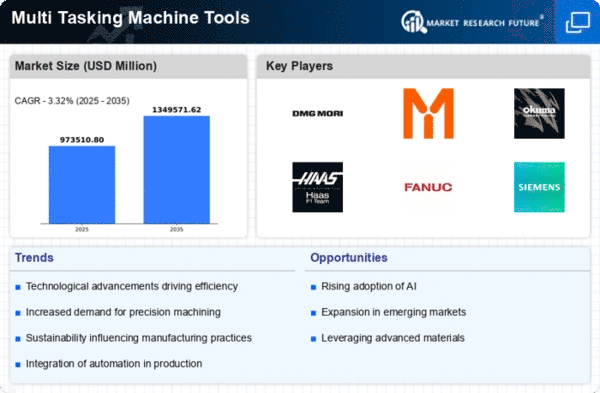

Multi Tasking Machine Tools Size

Multi Tasking Machine Tools Market Growth Projections and Opportunities

The global market for multi-tasking machine tools has witnessed substantial growth in recent years, with projections indicating a continued upward trajectory. Anticipated to reach USD 1,332.59 billion by 2028, the market is expected to exhibit a Compound Annual Growth Rate (CAGR) of 2.98% from 2021 to 2028. Several factors contribute to this growth, including increased demand from the manufacturing sector and the ongoing development of aerospace and defense infrastructure in emerging markets. Additionally, the proliferation of industrial activities presents significant opportunities for market players to capitalize on this expanding landscape. A key driver behind the robust growth of the global multi-tasking machine tools market is the escalating demand emanating from the manufacturing sector. As industries worldwide embrace advanced manufacturing technologies, the versatility and efficiency offered by multi-tasking machine tools become increasingly attractive. These tools, capable of performing multiple operations in a single setup, streamline production processes, reduce lead times, and enhance overall operational efficiency. This appeal has resulted in a rising adoption rate across various manufacturing verticals, contributing substantially to the market's expansion. The development of aerospace and defense infrastructure in emerging markets further propels the demand for multi-tasking machine tools. With the aerospace industry's increasing emphasis on precision and efficiency, these tools are well-suited to meet the complex machining requirements of aircraft components. From milling to turning and drilling, multi-tasking machine tools offer a comprehensive solution that aligns with the stringent standards of the aerospace sector. As emerging markets invest in bolstering their aerospace capabilities, the demand for these advanced machining tools is expected to surge, driving market growth. While the market presents lucrative opportunities, certain challenges may impede its progress. One notable obstacle is the high initial investment required for acquiring multi-tasking machine tools. These advanced machines come with a substantial upfront cost, which can be a deterrent for small and medium-sized enterprises (SMEs) or businesses with budget constraints. Additionally, the surging prices of steel, a critical material in the manufacturing of these machines, pose another challenge. The increase in steel prices can exert pressure on manufacturing costs, potentially limiting the affordability of multi-tasking machine tools for some end-users. Looking ahead, market players should focus on addressing these challenges by exploring cost-effective manufacturing processes, collaborating with financial institutions to provide flexible financing options, and investing in research and development to enhance the efficiency and cost-effectiveness of multi-tasking machine tools. Despite these challenges, the global multi-tasking machine tools market remains buoyant, driven by the increasing number of industrial activities. The ongoing industrialization and expansion of manufacturing capabilities across sectors such as automotive, electronics, and energy create a fertile ground for the adoption of multi-tasking machine tools. These machines, with their ability to perform various operations without the need for manual intervention, align well with the demands of modern, high-throughput manufacturing processes.

Leave a Comment