Regulatory Support

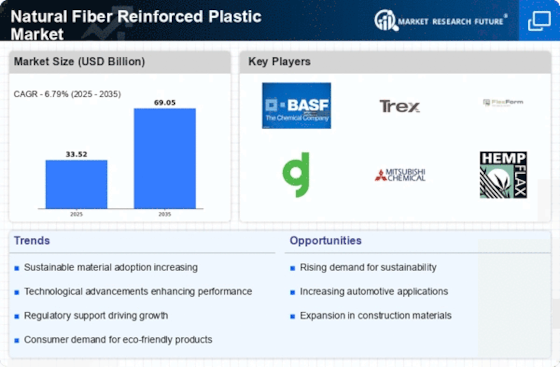

Regulatory frameworks promoting the use of sustainable materials are playing a crucial role in shaping the Natural Fiber Reinforced Plastic Market. Governments worldwide are implementing policies aimed at reducing plastic waste and encouraging the use of biodegradable materials. For example, regulations mandating the use of eco-friendly materials in automotive and construction sectors are driving demand for natural fiber composites. Market data indicates that regions with stringent environmental regulations are witnessing a surge in the adoption of natural fiber reinforced plastics, with a projected market share increase of 20% in the next five years. This regulatory support not only fosters innovation but also incentivizes manufacturers to invest in sustainable practices, thereby enhancing the overall growth trajectory of the Natural Fiber Reinforced Plastic Market.

Technological Innovations

Technological advancements in material science are significantly influencing the Natural Fiber Reinforced Plastic Market. Innovations in processing techniques, such as improved fiber treatment and composite formulation, are enhancing the performance characteristics of natural fiber composites. For instance, advancements in injection molding and extrusion processes are enabling manufacturers to produce high-quality products with better mechanical properties. Market data suggests that the adoption of these technologies could lead to a reduction in production costs by up to 15%, making natural fiber composites more appealing to manufacturers. Furthermore, the integration of smart technologies, such as sensors and IoT, into production processes is likely to optimize resource utilization and improve product quality. As a result, the Natural Fiber Reinforced Plastic Market is expected to experience robust growth driven by these technological innovations.

Sustainability Initiatives

The increasing emphasis on sustainability appears to be a primary driver for the Natural Fiber Reinforced Plastic Market. As consumers and manufacturers alike become more environmentally conscious, the demand for sustainable materials is rising. Natural fibers, such as hemp, jute, and flax, are renewable resources that offer a lower carbon footprint compared to traditional synthetic fibers. This shift towards eco-friendly alternatives is reflected in market data, indicating a projected growth rate of approximately 10% annually for natural fiber composites. Companies are increasingly investing in research and development to enhance the properties of these materials, making them more competitive against conventional plastics. The Natural Fiber Reinforced Plastic Market is thus positioned to benefit from this trend, as businesses seek to align their products with consumer preferences for sustainability.

Cost-Effectiveness of Natural Fibers

The cost-effectiveness of natural fibers is emerging as a key driver for the Natural Fiber Reinforced Plastic Market. Compared to synthetic alternatives, natural fibers often present a more economical option, particularly in regions where these materials are abundantly available. The lower raw material costs, combined with the potential for reduced energy consumption during production, make natural fiber composites an attractive choice for manufacturers. Market data indicates that the use of natural fibers can lower production costs by up to 20%, enhancing the competitiveness of products in various applications. As industries seek to optimize their supply chains and reduce costs, the Natural Fiber Reinforced Plastic Market is likely to see increased adoption of these materials, further driving market growth.

Consumer Demand for Eco-Friendly Products

The rising consumer demand for eco-friendly products is a significant driver for the Natural Fiber Reinforced Plastic Market. As awareness of environmental issues grows, consumers are increasingly seeking products that align with their values. This trend is particularly evident in sectors such as automotive, packaging, and consumer goods, where companies are responding by incorporating natural fiber composites into their offerings. Market data reveals that approximately 60% of consumers are willing to pay a premium for sustainable products, indicating a strong market potential for natural fiber reinforced plastics. This shift in consumer behavior is prompting manufacturers to innovate and expand their product lines, thereby contributing to the growth of the Natural Fiber Reinforced Plastic Market.

.png)