Government Initiatives and Support

Government initiatives aimed at promoting sustainable practices are significantly influencing the Natural Oil Polyols Market. Various countries are implementing policies that encourage the use of renewable resources and bio-based materials. For instance, subsidies and tax incentives for manufacturers utilizing natural oil polyols are becoming more common. These initiatives not only support the growth of the market but also foster innovation in product development. As governments continue to prioritize sustainability, the market for natural oil polyols is likely to benefit from increased funding and research opportunities, further solidifying its position in the materials sector.

Rising Demand for Bio-based Products

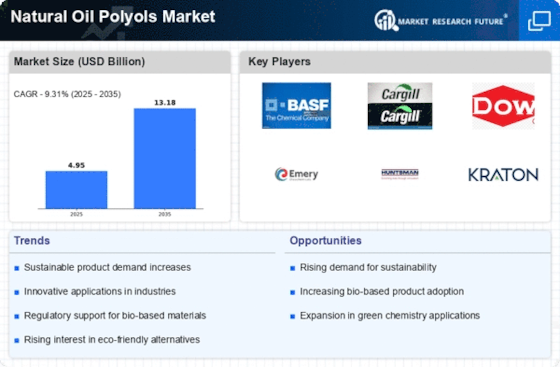

The increasing consumer preference for bio-based products is a pivotal driver for the Natural Oil Polyols Market. As environmental awareness grows, consumers are gravitating towards sustainable alternatives to petroleum-based products. This shift is reflected in the rising demand for bio-based polyols, which are derived from natural oils such as soy, castor, and palm. According to recent data, the bio-based polyols segment is projected to witness a compound annual growth rate of approximately 8% over the next few years. This trend not only aligns with consumer preferences but also encourages manufacturers to innovate and expand their product lines, thereby enhancing the overall market landscape.

Growing Awareness of Environmental Impact

The heightened awareness regarding the environmental impact of synthetic materials is propelling the Natural Oil Polyols Market forward. Consumers and businesses alike are increasingly recognizing the ecological benefits of using natural oil polyols, which are biodegradable and derived from renewable resources. This awareness is prompting companies to shift their sourcing strategies towards more sustainable options. Market analysis suggests that the demand for eco-friendly materials is expected to increase, with natural oil polyols playing a crucial role in this transition. As sustainability becomes a core value for many organizations, the market for natural oil polyols is poised for substantial growth.

Expanding Applications in Various Industries

The versatility of natural oil polyols is driving their adoption across multiple industries, including automotive, construction, and consumer goods. In the Natural Oil Polyols Market, these polyols are increasingly utilized in the production of flexible and rigid foams, coatings, adhesives, and sealants. The automotive sector, in particular, is experiencing a surge in demand for lightweight materials that contribute to fuel efficiency. Reports indicate that the use of natural oil polyols in automotive applications is expected to grow significantly, potentially reaching a market share of 25% by 2027. This expansion across diverse applications underscores the adaptability and potential of natural oil polyols.

Technological Innovations in Production Processes

Technological advancements in the production of natural oil polyols are enhancing efficiency and reducing costs, thereby driving growth in the Natural Oil Polyols Market. Innovations such as enzymatic processes and improved extraction techniques are enabling manufacturers to produce high-quality polyols with lower environmental impact. These advancements not only streamline production but also improve the properties of the final products, making them more appealing to consumers and industries alike. As technology continues to evolve, it is anticipated that the market will see a rise in the introduction of novel formulations and applications, further expanding its reach.