Expansion of Manufacturing Sector

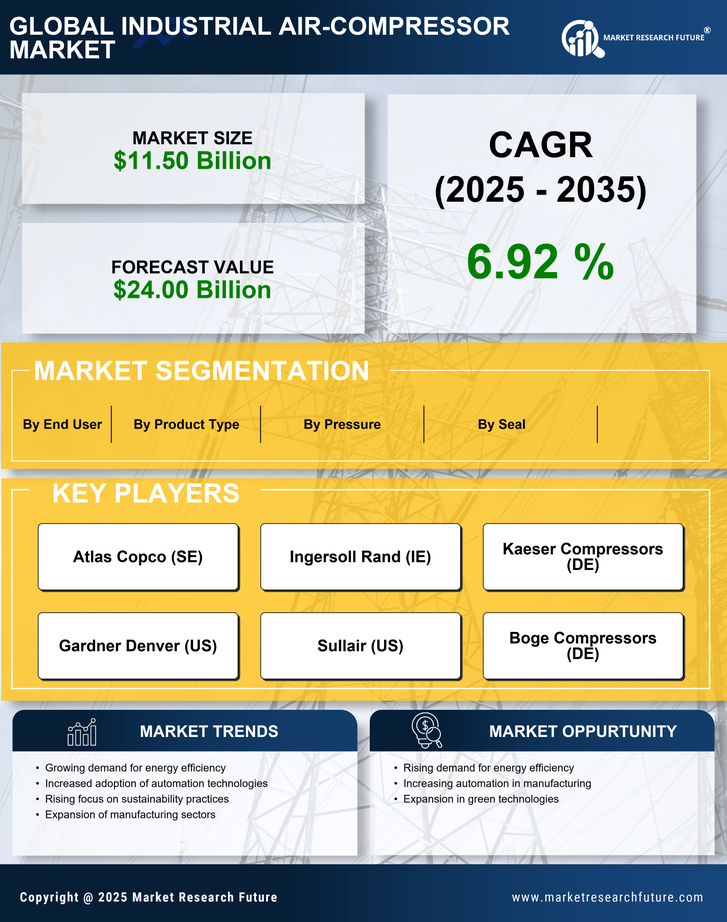

The industrial air-compressor market in North America is benefiting from the expansion of the manufacturing sector. As manufacturing activities ramp up, the need for reliable and efficient air compressors becomes increasingly critical. The manufacturing sector has shown a growth rate of approximately 3% annually, which directly correlates with the demand for industrial air compressors. These compressors are essential for various applications, including pneumatic tools, material handling, and assembly lines. The growth in manufacturing not only boosts the demand for air compressors but also encourages innovation in compressor technology, further propelling the industrial air-compressor market forward.

Growth in Renewable Energy Sector

The growth of the renewable energy sector is emerging as a significant driver for the industrial air-compressor market in North America. As the demand for renewable energy sources such as wind and solar power increases, the need for efficient air compression systems to support these technologies is also rising. Air compressors play a vital role in various renewable energy applications, including the operation of pneumatic systems in wind turbines and solar panel manufacturing. The renewable energy sector is projected to grow at a compound annual growth rate (CAGR) of over 10% in the coming years, which could substantially boost the demand for industrial air compressors tailored for these applications.

Increased Automation in Industries

The trend towards increased automation in various industries is significantly impacting the industrial air-compressor market in North America. Automation technologies require reliable and efficient air supply systems, which are often provided by advanced air compressors. As industries adopt automation to enhance productivity and reduce labor costs, the demand for sophisticated air compressor systems is likely to rise. This shift is evident in sectors such as automotive, food and beverage, and pharmaceuticals, where automated processes rely heavily on compressed air. The industrial air-compressor market is thus poised for growth as companies invest in automation and the necessary supporting technologies.

Regulatory Compliance and Standards

Regulatory compliance is becoming a crucial driver for the industrial air-compressor market in North America. Industries are increasingly required to adhere to stringent regulations regarding emissions and energy consumption. Compliance with these regulations often necessitates the adoption of advanced air compressor technologies that meet specific performance and environmental standards. For instance, the implementation of regulations aimed at reducing greenhouse gas emissions is pushing companies to invest in more efficient and environmentally friendly air compressors. This trend not only drives innovation but also expands the market for compliant products, thereby enhancing the overall growth of the industrial air-compressor market.

Rising Demand for Energy Efficiency

The industrial air-compressor market in North America is experiencing a notable shift towards energy efficiency. As industries strive to reduce operational costs, the demand for energy-efficient air compressors is increasing. According to recent data, energy costs can account for up to 70% of the total lifecycle costs of air compressors. This has led manufacturers to innovate and develop compressors that consume less energy while maintaining performance. The focus on energy efficiency not only helps companies save on energy bills but also aligns with broader sustainability goals. Consequently, the industrial air-compressor market is likely to see a surge in products that meet these energy efficiency standards, thereby driving market growth.