Diverse Applications

The diverse applications of olefin block copolymers are a significant driver for the Olefin Block Copolymer Market. These materials are utilized across various sectors, including automotive, healthcare, and consumer products, due to their unique properties such as flexibility, durability, and resistance to chemicals. In 2025, the automotive sector is anticipated to account for a substantial share of the market, driven by the need for lightweight and high-performance materials. Additionally, the healthcare industry is increasingly adopting olefin block copolymers for medical devices and packaging, further expanding their market reach. This versatility in applications not only enhances the demand for olefin block copolymers but also encourages manufacturers to innovate and diversify their product offerings.

Regulatory Compliance

Regulatory compliance is emerging as a crucial driver for the Olefin Block Copolymer Market. Governments worldwide are implementing stringent regulations regarding the use of materials in various applications, particularly in packaging and automotive sectors. Compliance with these regulations often necessitates the use of advanced materials like olefin block copolymers, which offer superior performance and safety characteristics. As of 2025, the market is expected to witness a surge in demand for compliant materials, with olefin block copolymers being favored for their ability to meet these standards. This trend is likely to compel manufacturers to focus on developing products that not only comply with regulations but also provide enhanced functionality, thereby driving market growth.

Sustainability Initiatives

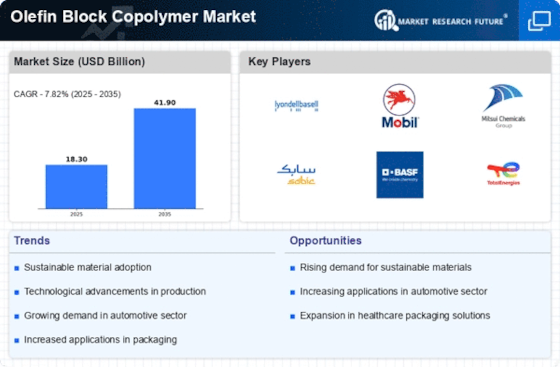

The increasing emphasis on sustainability initiatives appears to be a pivotal driver for the Olefin Block Copolymer Market. As industries strive to reduce their carbon footprints, the demand for eco-friendly materials is on the rise. Olefin block copolymers, known for their recyclability and lower environmental impact, are gaining traction. In 2025, the market for sustainable materials is projected to reach approximately 200 billion USD, with olefin block copolymers playing a significant role. This shift towards sustainable practices not only aligns with regulatory requirements but also meets consumer preferences for environmentally responsible products. Consequently, manufacturers are likely to invest in the development of innovative olefin block copolymer solutions that cater to these sustainability goals, thereby enhancing their market presence.

Technological Advancements

Technological advancements in polymer processing and formulation are driving the Olefin Block Copolymer Market forward. Innovations in production techniques, such as metallocene catalysis, have enabled the creation of olefin block copolymers with enhanced properties, including improved elasticity and thermal stability. These advancements are expected to contribute to a market growth rate of around 5% annually through 2025. Furthermore, the integration of smart technologies in manufacturing processes is likely to optimize production efficiency and reduce costs. As a result, companies are increasingly adopting advanced technologies to develop high-performance olefin block copolymers that meet the evolving demands of various applications, including automotive, packaging, and consumer goods.

Economic Growth in Emerging Markets

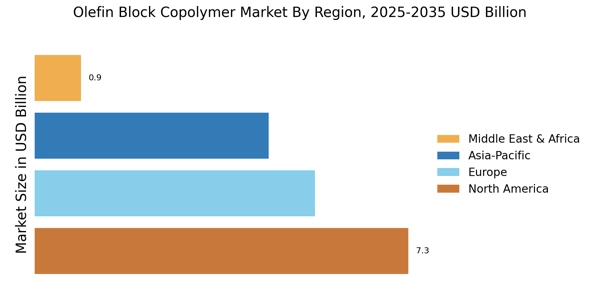

Economic growth in emerging markets is likely to serve as a significant driver for the Olefin Block Copolymer Market. As these economies expand, there is an increasing demand for consumer goods, automotive components, and packaging solutions, all of which utilize olefin block copolymers. In 2025, it is projected that emerging markets will contribute to approximately 30% of the overall market growth for olefin block copolymers. This growth is attributed to rising disposable incomes and changing consumer preferences towards high-quality products. Consequently, manufacturers are expected to focus on these regions, tailoring their offerings to meet local demands and preferences, thereby enhancing their competitive edge in the market.