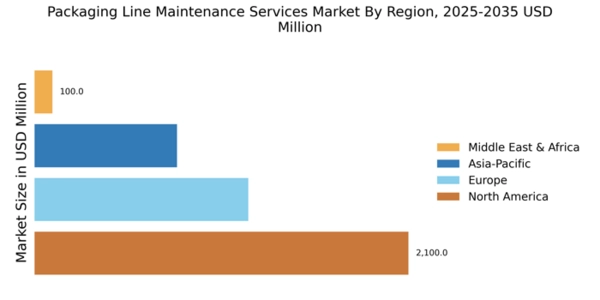

North America : Market Leader in Maintenance Services

North America is poised to maintain its leadership in the Packaging Line Maintenance Services Market, holding a significant market share of $2100.0M in 2024. The region's growth is driven by increasing automation in manufacturing, stringent regulatory standards, and a rising demand for efficient packaging solutions. Companies are investing in advanced technologies to enhance operational efficiency and reduce downtime, further propelling market growth.

The competitive landscape in North America is robust, featuring key players such as Rockwell Automation, Honeywell, and Emerson Electric. The U.S. stands out as the leading country, supported by a strong industrial base and innovation in packaging technologies. The presence of major corporations fosters a dynamic environment for service providers, ensuring a continuous demand for maintenance services in the packaging sector.

Europe : Emerging Hub for Innovation

Europe is witnessing a significant transformation in the Packaging Line Maintenance Services Market, with a market size of $1200.0M. The region's growth is fueled by a strong emphasis on sustainability and compliance with environmental regulations. European manufacturers are increasingly adopting eco-friendly packaging solutions, which necessitate regular maintenance and upgrades of packaging lines to meet new standards and consumer expectations.

Leading countries such as Germany, France, and the UK are at the forefront of this shift, with major players like Tetra Pak and Krones AG driving innovation. The competitive landscape is characterized by a mix of established firms and emerging startups focused on sustainable practices. This dynamic environment is expected to enhance service demand, ensuring a thriving market for maintenance services.

Asia-Pacific : Rapid Growth and Expansion

Asia-Pacific is rapidly emerging as a key player in the Packaging Line Maintenance Services Market, with a market size of $800.0M. The region's growth is driven by increasing urbanization, rising disposable incomes, and a growing demand for packaged goods. Countries like China and India are experiencing significant industrial growth, leading to heightened investments in packaging technologies and maintenance services to enhance production efficiency.

China is the leading country in this region, supported by a vast manufacturing base and a focus on automation. The competitive landscape includes both local and international players, such as FANUC and Schneider Electric, who are expanding their presence to cater to the growing demand. This competitive environment is expected to drive innovation and service quality in the packaging maintenance sector.

Middle East and Africa : Emerging Market Potential

The Middle East and Africa region is gradually emerging in the Packaging Line Maintenance Services Market, with a market size of $100.0M. The growth is primarily driven by increasing investments in the food and beverage sector, coupled with a rising demand for efficient packaging solutions. Regulatory frameworks are evolving, encouraging manufacturers to adopt advanced maintenance practices to ensure compliance and enhance operational efficiency.

Countries like South Africa and the UAE are leading the way, with a growing number of local and international players entering the market. The competitive landscape is characterized by a mix of established firms and new entrants, creating opportunities for service providers to innovate and expand their offerings. This region holds significant potential for growth in the coming years, driven by increasing industrial activities.