Expansion of End-Use Industries

The Paste PVC Resin Market is experiencing growth due to the expansion of various end-use industries, including packaging, healthcare, and consumer goods. As these industries evolve, the demand for high-quality and versatile materials increases, positioning Paste PVC resin as a key player. In the packaging sector, for instance, the need for flexible and durable materials is driving the adoption of Paste PVC resin in films and containers. Additionally, the healthcare industry is utilizing this resin for medical devices and packaging due to its biocompatibility and safety. The projected growth rates in these end-use sectors suggest that the Paste PVC Resin Market will continue to thrive, driven by the diverse applications and the need for innovative material solutions. The PVCs share price continues to reflect strong market demand and steady industrial growth.

Growth in Automotive Applications

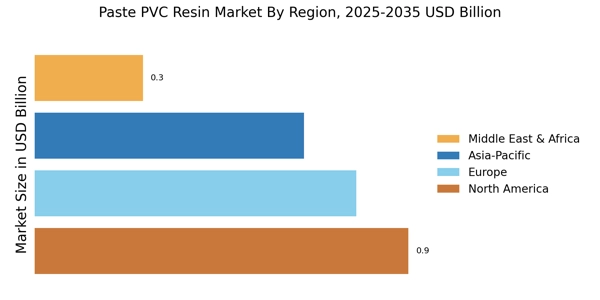

The Paste PVC Resin Market is witnessing a significant uptick in its application within the automotive sector. As manufacturers increasingly prioritize lightweight and durable materials, Paste PVC resin emerges as a preferred choice for interior and exterior components. The automotive industry is projected to grow steadily, with an estimated increase in production rates, which could lead to a heightened demand for Paste PVC resin. This resin is utilized in various automotive applications, including dashboards, door panels, and wiring insulation, due to its excellent thermal stability and resistance to chemicals. The ongoing evolution of automotive design and technology suggests that the Paste PVC Resin Market will play a crucial role in meeting the material needs of this dynamic sector.

Innovations in Product Formulation

The Paste PVC Resin Market is benefiting from continuous innovations in product formulation, which enhance the performance and versatility of the resin. Manufacturers are increasingly focusing on developing specialized formulations that cater to specific applications, such as high-performance coatings and adhesives. These innovations not only improve the mechanical properties of Paste PVC resin but also contribute to sustainability efforts by reducing the environmental impact of production processes. Recent advancements indicate that the introduction of bio-based additives and eco-friendly production methods could reshape the market landscape. As these innovations gain traction, the Paste PVC Resin Market is likely to experience a shift towards more sustainable and high-performance products, appealing to a broader range of industries.

Rising Demand in Construction Sector

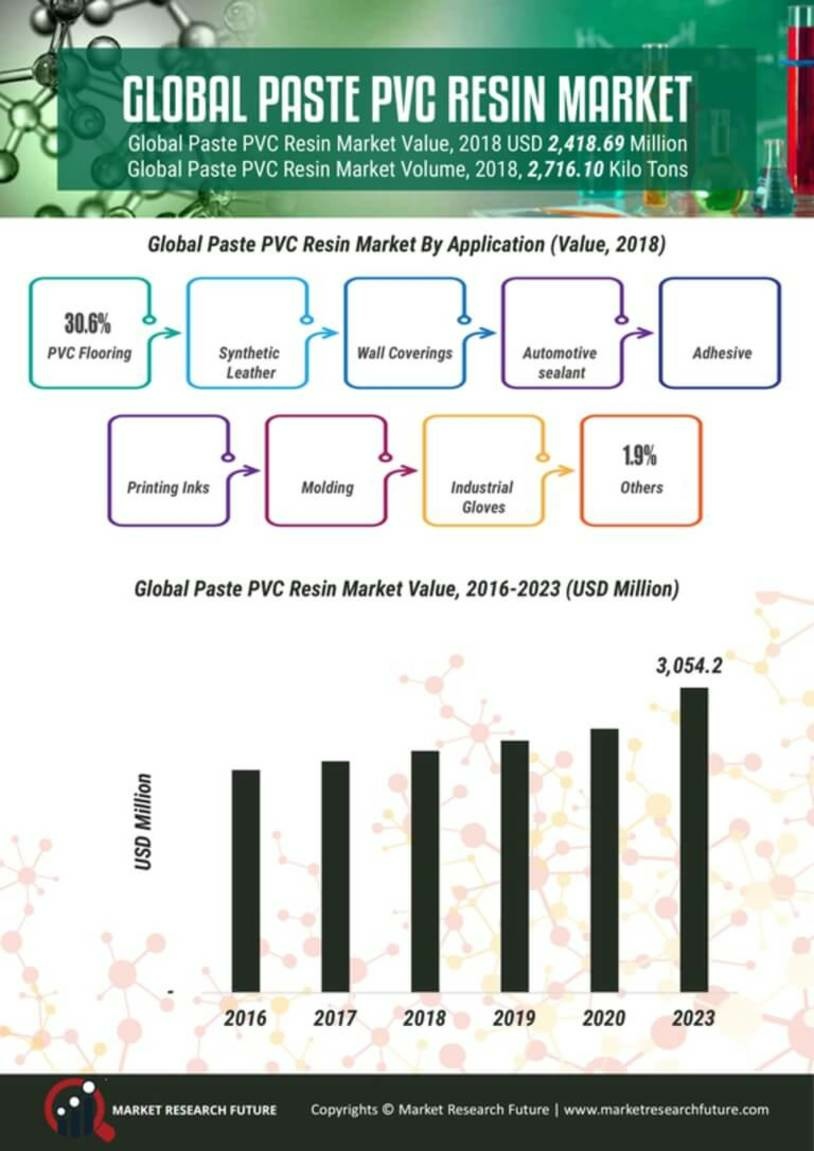

The Paste PVC Resin Market is experiencing a notable surge in demand, primarily driven by the construction sector. As urbanization accelerates, the need for durable and versatile materials in building applications becomes increasingly critical. Paste PVC resin is favored for its excellent adhesion properties and resistance to environmental factors, making it ideal for various construction materials, including flooring, wall coverings, and pipes. Recent data indicates that the construction industry is projected to grow at a compound annual growth rate of approximately 5% over the next few years, further propelling the demand for Paste PVC resin. This trend suggests that the Paste PVC Resin Market will continue to thrive as construction activities expand, necessitating innovative and sustainable material solutions.

Regulatory Support for Sustainable Materials

The Paste PVC Resin Market is poised to benefit from increasing regulatory support aimed at promoting sustainable materials. Governments and regulatory bodies are implementing policies that encourage the use of environmentally friendly materials in various applications, including construction and automotive. This regulatory landscape is likely to drive demand for Paste PVC resin, particularly formulations that meet stringent environmental standards. As industries adapt to these regulations, the Paste PVC Resin Market may see a shift towards more sustainable practices, including the use of recycled materials and reduced emissions during production. This trend suggests that the market will not only grow but also evolve in response to regulatory pressures, fostering innovation and sustainability.