Regulatory Support and Standards

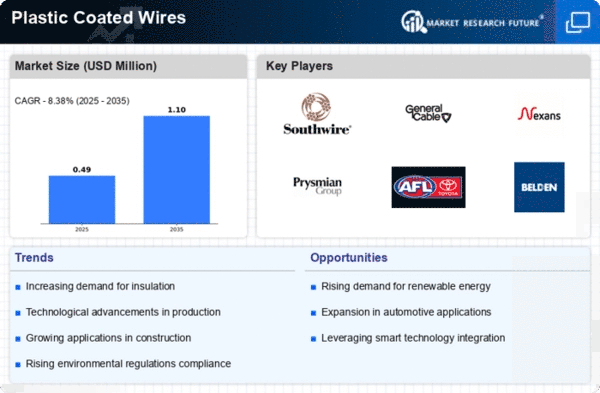

Regulatory support and established standards significantly impact the Global Plastic-coated Wires Market Industry. Governments worldwide are implementing stringent regulations to ensure safety and quality in electrical installations, which in turn drives the demand for high-quality plastic-coated wires. Compliance with these regulations often necessitates the use of advanced wiring solutions that meet specific safety standards. This regulatory environment encourages manufacturers to innovate and improve their products, thereby enhancing market growth. As the industry adapts to these regulations, it is likely to experience a steady increase in demand, contributing to a projected CAGR of 4.53% from 2025 to 2035.

Growth in Renewable Energy Sector

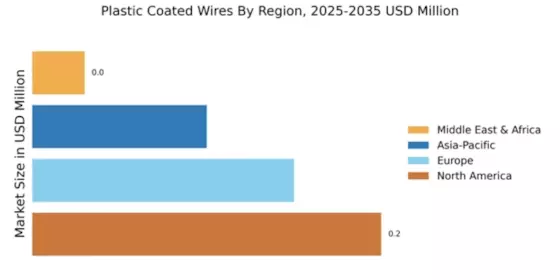

The Global Plastic-coated Wires Market Industry is significantly influenced by the expansion of the renewable energy sector. As countries worldwide shift towards sustainable energy sources, the demand for efficient wiring solutions in solar and wind energy systems increases. Plastic-coated wires are favored for their resistance to environmental degradation, making them suitable for outdoor installations. This trend is particularly evident in regions investing heavily in renewable energy infrastructure. The industry's growth is further supported by government initiatives promoting clean energy, which are likely to enhance the market's value, potentially reaching 8.96 USD Million by 2035.

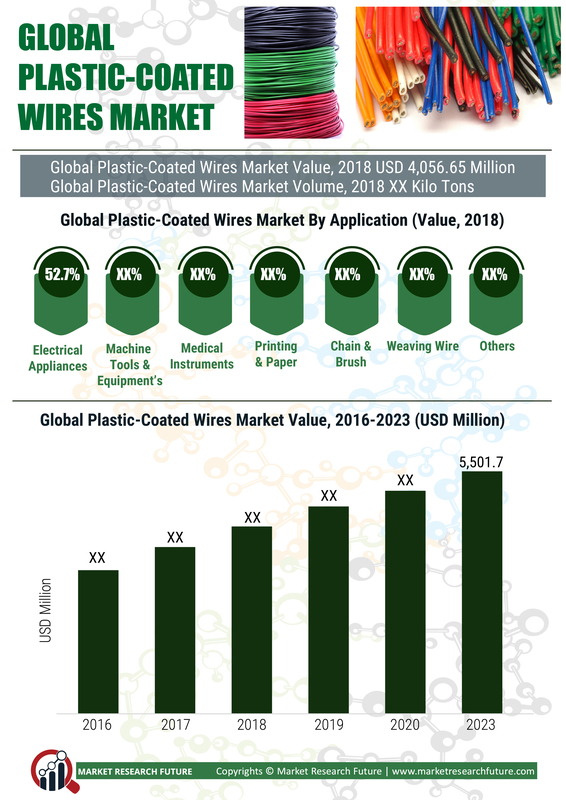

Market Trends and Growth Projections

The Global Plastic-coated Wires Market Industry is characterized by various trends and growth projections that indicate its potential trajectory. With a market value of 5.5 USD Million in 2024, the industry is poised for substantial growth, driven by factors such as technological advancements and increasing demand in electrical applications. Projections suggest that by 2035, the market could reach 8.96 USD Million, reflecting a robust CAGR of 4.53% from 2025 to 2035. These trends highlight the industry's resilience and adaptability in meeting the evolving needs of various sectors, ensuring a promising future for plastic-coated wires.

Rising Demand in Electrical Applications

The Global Plastic-coated Wires Market Industry experiences a notable surge in demand driven by the increasing use of plastic-coated wires in electrical applications. These wires provide enhanced insulation and protection against environmental factors, making them ideal for various electrical installations. For instance, the construction sector is increasingly adopting these wires for wiring systems, contributing to the industry's growth. As of 2024, the market is projected to reach 5.5 USD Million, reflecting a growing trend towards safer and more efficient electrical solutions. This demand is expected to continue, with projections indicating a market value of 8.96 USD Million by 2035.

Technological Advancements in Manufacturing

Technological advancements play a pivotal role in shaping the Global Plastic-coated Wires Market Industry. Innovations in manufacturing processes, such as extrusion and coating technologies, enhance the quality and performance of plastic-coated wires. These advancements not only improve the durability and flexibility of the wires but also reduce production costs, making them more accessible to various industries. The integration of automation in manufacturing processes further streamlines production, allowing for higher output and efficiency. As a result, the industry is likely to witness sustained growth, with a projected CAGR of 4.53% from 2025 to 2035, indicating a robust future for plastic-coated wire applications.

Increasing Urbanization and Infrastructure Development

Urbanization and infrastructure development are key drivers of the Global Plastic-coated Wires Market Industry. As urban areas expand, the demand for reliable electrical wiring solutions rises, particularly in residential and commercial buildings. Plastic-coated wires are preferred for their safety features and longevity, making them suitable for modern construction projects. Governments and private sectors are investing in infrastructure projects, which further fuels the demand for these wires. The market is expected to grow significantly, with projections indicating a value of 5.5 USD Million in 2024, reflecting the ongoing trend of urbanization and the need for efficient electrical systems.