Innovations in Manufacturing Processes

Innovations in manufacturing processes are reshaping the landscape of the Polyamide in Electronic Protection Device Market. Advances in production techniques, such as 3D printing and injection molding, enable the creation of complex geometries and customized solutions using polyamide. These innovations not only enhance the efficiency of manufacturing but also reduce waste, aligning with sustainability goals. Data suggests that the adoption of advanced manufacturing technologies is expected to increase by 15% in the coming years. This shift towards innovative production methods is likely to drive the demand for polyamide in electronic protection devices, as manufacturers seek to leverage these technologies for improved product performance and design flexibility.

Enhanced Thermal Stability Requirements

The need for enhanced thermal stability in electronic devices is driving the adoption of polyamide in the Electronic Protection Device Market. As electronic components become more compact and powerful, they generate significant heat, necessitating materials that can withstand elevated temperatures without degrading. Polyamide exhibits excellent thermal resistance, making it suitable for applications in high-performance electronics. Market analysis indicates that the demand for materials with superior thermal properties is expected to rise, with a projected increase of 10% in the next few years. This growing requirement for thermal stability positions polyamide as a preferred choice for manufacturers seeking reliable solutions in electronic protection devices.

Rising Demand for Lightweight Materials

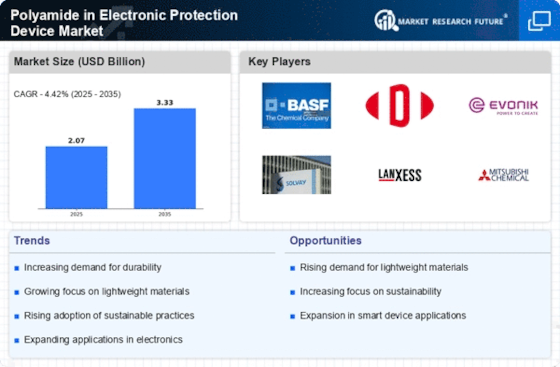

The increasing demand for lightweight materials in the electronics sector is a notable driver for the Polyamide in Electronic Protection Device Market. As manufacturers strive to enhance the portability and efficiency of electronic devices, polyamide's lightweight properties become increasingly appealing. This material not only reduces the overall weight of devices but also contributes to improved energy efficiency. According to recent data, the lightweight materials market is projected to grow at a compound annual growth rate of approximately 8% over the next five years. This trend suggests that polyamide will play a crucial role in meeting the evolving needs of consumers and manufacturers alike, thereby bolstering its position in the electronic protection device sector.

Growth of the Consumer Electronics Sector

The expansion of the consumer electronics sector serves as a significant driver for the Polyamide in Electronic Protection Device Market. With the proliferation of smart devices, wearables, and other electronic gadgets, the demand for effective protection solutions is on the rise. Polyamide's versatility and protective qualities make it an ideal choice for safeguarding sensitive electronic components. Market forecasts suggest that the consumer electronics industry will experience a growth rate of approximately 6% annually over the next five years. This growth trajectory indicates a corresponding increase in the demand for polyamide-based protection devices, as manufacturers seek to enhance the durability and reliability of their products.

Regulatory Compliance and Safety Standards

The Polyamide in Electronic Protection Device Market is significantly influenced by stringent regulatory compliance and safety standards. As governments and regulatory bodies impose stricter guidelines on electronic products, manufacturers are compelled to utilize materials that meet these requirements. Polyamide, known for its durability and resistance to environmental factors, aligns well with these safety standards. Recent data indicates that compliance-related costs in the electronics sector are rising, prompting manufacturers to invest in materials that ensure adherence to regulations. This trend not only enhances product safety but also drives the demand for polyamide in electronic protection devices, as companies seek to mitigate risks associated with non-compliance.