Sustainability Initiatives

The Prepreg Pre-Impregnated Composite Fiber Market is increasingly influenced by sustainability initiatives. As industries strive to reduce their carbon footprints, the demand for eco-friendly materials rises. Prepreg composites, known for their lightweight and high-strength properties, align well with these initiatives. They contribute to energy efficiency in applications such as aerospace and automotive, where weight reduction is crucial. The market is projected to grow as manufacturers adopt greener practices, with a focus on recycling and reusability of composite materials. This shift not only meets regulatory requirements but also appeals to environmentally conscious consumers, thereby enhancing market potential. Furthermore, the integration of bio-based resins in prepreg production is gaining traction, indicating a promising trend towards sustainable manufacturing processes.

Technological Advancements

Technological advancements play a pivotal role in shaping the Prepreg Pre-Impregnated Composite Fiber Market. Innovations in manufacturing processes, such as automated fiber placement and advanced curing techniques, enhance the efficiency and quality of prepreg materials. These advancements enable the production of complex geometries and reduce waste, which is particularly beneficial in sectors like aerospace, where precision is paramount. The market is witnessing a surge in research and development activities aimed at improving the performance characteristics of prepreg composites. For instance, the introduction of high-temperature resistant prepregs is expanding their application scope, particularly in the automotive sector, where performance under extreme conditions is essential. As technology continues to evolve, it is likely to drive further growth in the market, fostering new applications and enhancing material properties.

Growing Demand in Aerospace and Automotive

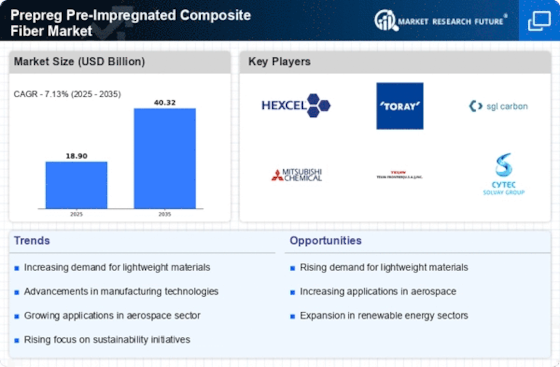

The Prepreg Pre-Impregnated Composite Fiber Market is experiencing robust growth driven by increasing demand in the aerospace and automotive sectors. The aerospace industry, in particular, is leveraging prepreg composites for their lightweight and high-strength attributes, which contribute to fuel efficiency and performance. According to recent estimates, the aerospace segment is expected to account for a substantial share of the market, with a projected CAGR of over 10% in the coming years. Similarly, the automotive sector is increasingly adopting prepreg materials to meet stringent regulations on emissions and fuel economy. The shift towards electric vehicles further amplifies this demand, as manufacturers seek lightweight materials to enhance battery efficiency. This dual demand from aerospace and automotive industries is likely to propel the growth of the prepreg market significantly.

Regulatory Support and Standards Development

Regulatory support and standards development are increasingly influencing the Prepreg Pre-Impregnated Composite Fiber Market. Governments and regulatory bodies are establishing guidelines that promote the use of advanced composite materials in various applications. These regulations often focus on safety, performance, and environmental impact, encouraging industries to adopt prepreg composites. For example, aerospace regulations are becoming more stringent, necessitating the use of high-performance materials that meet specific safety standards. This regulatory landscape not only drives demand but also fosters innovation as manufacturers strive to comply with evolving standards. Furthermore, the establishment of industry standards for prepreg materials enhances market credibility and facilitates wider adoption across sectors. As regulatory frameworks continue to evolve, they are likely to play a crucial role in shaping the future of the prepreg market.

Increased Investment in Research and Development

Increased investment in research and development is a critical driver for the Prepreg Pre-Impregnated Composite Fiber Market. As industries recognize the potential of prepreg composites, funding for R&D initiatives has surged. This investment aims to enhance material properties, develop new applications, and improve manufacturing processes. For instance, research into hybrid composites that combine different fiber types is gaining momentum, potentially leading to superior performance characteristics. Additionally, collaborations between academic institutions and industry players are fostering innovation, resulting in the introduction of advanced prepreg formulations. The focus on developing cost-effective production methods is also noteworthy, as it could make prepreg materials more accessible to a broader range of industries. This trend of increased R&D investment is expected to drive market growth and expand the application landscape for prepreg composites.

.png)