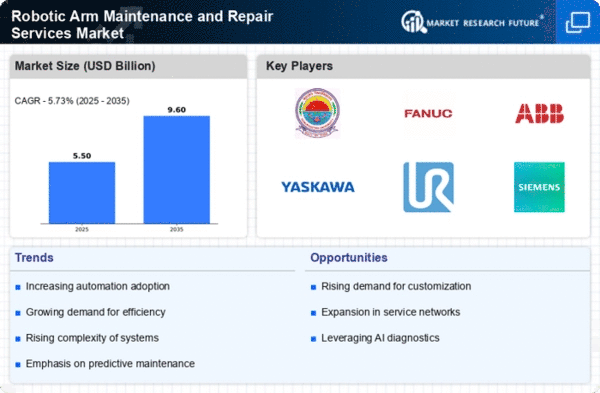

The Robotic Arm Maintenance and Repair Services Market is characterized by a dynamic competitive landscape, driven by technological advancements and increasing automation across various industries. Key players such as KUKA (DE), FANUC (JP), and ABB (CH) are at the forefront, each adopting distinct strategies to enhance their market positioning. KUKA (DE) focuses on innovation through the development of advanced robotic solutions, while FANUC (JP) emphasizes digital transformation and AI integration to optimize operational efficiency. ABB (CH) is actively pursuing strategic partnerships to expand its service offerings, thereby enhancing its competitive edge. Collectively, these strategies contribute to a robust competitive environment, fostering continuous improvement and adaptation among market participants.In terms of business tactics, companies are increasingly localizing manufacturing to reduce lead times and enhance supply chain resilience. This approach is particularly relevant in a moderately fragmented market where the collective influence of key players shapes overall dynamics. The emphasis on supply chain optimization is evident as firms strive to maintain operational continuity and meet the growing demand for maintenance and repair services.

In November KUKA (DE) announced a strategic partnership with a leading AI firm to enhance predictive maintenance capabilities for its robotic systems. This collaboration is poised to revolutionize service delivery by enabling real-time monitoring and proactive interventions, thereby reducing downtime and operational costs for clients. Such initiatives underscore KUKA's commitment to leveraging cutting-edge technology to improve service efficiency and customer satisfaction.Similarly, in October 2025, ABB (CH) launched a new service platform that integrates IoT technology to provide clients with comprehensive insights into their robotic systems' performance. This platform not only facilitates remote diagnostics but also enhances the overall maintenance process, allowing for timely interventions. The strategic importance of this launch lies in ABB's ability to offer value-added services that differentiate it from competitors, thereby solidifying its market position.

In December FANUC (JP) unveiled a new training program aimed at upskilling technicians in robotic maintenance and repair. This initiative reflects FANUC's recognition of the critical need for skilled labor in the evolving landscape of automation. By investing in workforce development, FANUC not only addresses current skill gaps but also positions itself as a leader in fostering industry expertise, which is essential for sustaining competitive advantage.

As of December the market is witnessing a pronounced shift towards digitalization, sustainability, and AI integration. These trends are reshaping competitive dynamics, with strategic alliances becoming increasingly pivotal in driving innovation and enhancing service offerings. The focus is shifting from price-based competition to differentiation through technology and reliability in supply chains. Looking ahead, companies that prioritize innovation and adaptability are likely to thrive, as the landscape continues to evolve in response to emerging technologies and market demands.