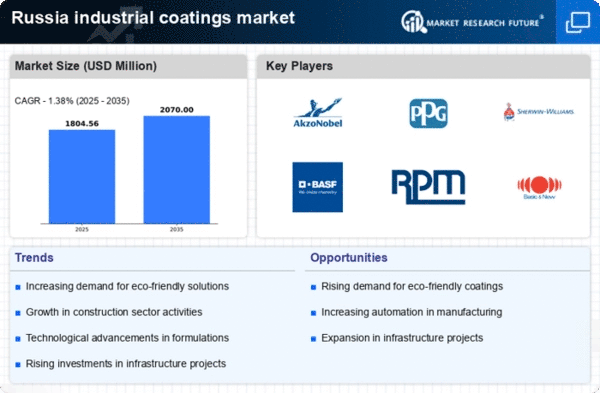

The industrial coatings market in Russia is characterized by a competitive landscape that is increasingly shaped by innovation, sustainability, and strategic partnerships. Key players such as AkzoNobel (NL), PPG Industries (US), and BASF (DE) are actively pursuing growth through various strategies, including regional expansion and technological advancements. These companies are not only focusing on enhancing their product offerings but are also investing in sustainable practices to meet the evolving demands of the market. The collective efforts of these firms contribute to a dynamic environment where competition is driven by the need for high-performance coatings that comply with environmental regulations.In terms of business tactics, companies are localizing manufacturing to reduce costs and improve supply chain efficiency. This approach appears to be particularly relevant in the context of the Russian market, where logistical challenges can impact operational effectiveness. The market structure is moderately fragmented, with several key players holding substantial market shares. The influence of these major companies is significant, as they set benchmarks for quality and innovation that smaller firms often strive to meet.

In October AkzoNobel (NL) announced the opening of a new manufacturing facility in Russia, aimed at increasing its production capacity for high-performance coatings. This strategic move is likely to enhance the company's ability to serve local customers more effectively while reducing lead times. The establishment of this facility underscores AkzoNobel's commitment to regional growth and its focus on meeting the specific needs of the Russian market.

In September PPG Industries (US) launched a new line of eco-friendly coatings designed to reduce environmental impact. This initiative aligns with the growing trend towards sustainability in the coatings industry and positions PPG as a leader in providing innovative solutions. The introduction of these products not only caters to consumer demand for greener options but also strengthens PPG's competitive edge in a market that increasingly values environmental responsibility.

In August BASF (DE) entered into a strategic partnership with a local distributor to enhance its market presence in Russia. This collaboration is expected to improve BASF's distribution capabilities and expand its reach within the region. By leveraging local expertise, BASF aims to better understand customer preferences and adapt its offerings accordingly, which could lead to increased market share and customer loyalty.

As of November the competitive trends in the industrial coatings market are heavily influenced by digitalization, sustainability, and the integration of advanced technologies such as AI. Strategic alliances are becoming more prevalent, as companies recognize the value of collaboration in navigating complex market dynamics. Looking ahead, it is anticipated that competitive differentiation will increasingly rely on innovation and technology rather than solely on price. Firms that prioritize supply chain reliability and sustainable practices are likely to emerge as leaders in this evolving landscape.