Growth in Automotive Production

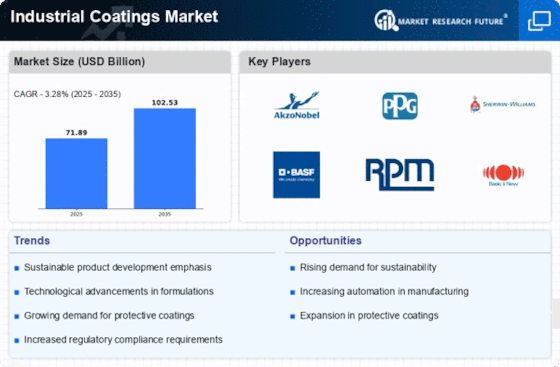

The Industrial Coatings Market is experiencing a surge in demand due to the growth in automotive production, which is a key driver of the coatings sector. As automotive manufacturers strive to enhance vehicle aesthetics and durability, the need for high-quality coatings becomes paramount. In 2025, the automotive segment is projected to represent approximately 25% of the total industrial coatings market. This growth is fueled by the increasing production of electric vehicles and the adoption of lightweight materials, which require specialized coatings for optimal performance. Furthermore, the emphasis on sustainability within the automotive industry encourages the use of eco-friendly coatings, aligning with consumer preferences and regulatory requirements. Consequently, the Industrial Coatings Market is likely to benefit from the ongoing transformation within the automotive sector.

Expansion of the Construction Sector

The Industrial Coatings Market is significantly influenced by the expansion of the construction sector, which is experiencing robust growth across various regions. The increasing number of infrastructure projects, including residential, commercial, and industrial developments, drives the demand for high-performance coatings. In 2025, the construction industry is expected to contribute around 30% to the overall demand for industrial coatings. This growth is attributed to the rising need for aesthetic appeal, durability, and protection against weathering in construction materials. Furthermore, the trend towards sustainable building practices encourages the use of eco-friendly coatings, which aligns with the evolving preferences of consumers and regulatory bodies. Consequently, the Industrial Coatings Market is poised for growth as it adapts to the changing dynamics of the construction landscape.

Rising Demand for Protective Coatings

The Industrial Coatings Market experiences a notable increase in demand for protective coatings, driven by the need to enhance durability and resistance against environmental factors. Industries such as automotive, aerospace, and construction are increasingly adopting these coatings to prolong the lifespan of their products. In 2025, the protective coatings segment is projected to account for approximately 40% of the total market share, reflecting a growing awareness of the benefits of corrosion resistance and surface protection. This trend is further supported by stringent regulations aimed at reducing environmental impact, compelling manufacturers to invest in advanced coating technologies. As a result, the Industrial Coatings Market is likely to witness sustained growth, with innovations in formulation and application techniques enhancing the performance of protective coatings.

Regulatory Compliance and Environmental Standards

Regulatory compliance and environmental standards are critical factors influencing the Industrial Coatings Market, as manufacturers face increasing pressure to adhere to stringent regulations. Governments worldwide are implementing policies aimed at reducing emissions and promoting sustainable practices, which directly impact the formulation and application of industrial coatings. In 2025, it is expected that compliance with these regulations will drive innovation in low-VOC and eco-friendly coatings, potentially accounting for a significant share of the market. This shift not only addresses environmental concerns but also aligns with the growing consumer demand for sustainable products. As a result, the Industrial Coatings Market is likely to witness a transformation, with manufacturers investing in research and development to create compliant and environmentally friendly coating solutions.

Technological Innovations in Coating Applications

Technological innovations play a pivotal role in shaping the Industrial Coatings Market, as advancements in application techniques and product formulations enhance performance and efficiency. Innovations such as powder coatings, high solids coatings, and waterborne coatings are gaining traction due to their environmental benefits and superior properties. In 2025, it is anticipated that these advanced technologies will account for a significant portion of the market, driven by the need for faster application processes and reduced VOC emissions. Additionally, the integration of automation and robotics in coating applications is likely to improve precision and reduce labor costs. As a result, the Industrial Coatings Market is expected to evolve, with manufacturers focusing on research and development to create innovative solutions that meet the demands of various end-use sectors.