Sustainability Initiatives

Sustainability is becoming increasingly pivotal within the Shot Blasting Machine Market. As industries strive to reduce their environmental footprint, the demand for eco-friendly shot blasting solutions is on the rise. Manufacturers are now focusing on developing machines that utilize recyclable materials and generate less waste. Additionally, the implementation of closed-loop systems in shot blasting processes minimizes the release of harmful particles into the environment. Recent studies suggest that companies adopting sustainable practices in their operations can enhance their market competitiveness. The shift towards sustainability is not merely a trend; it is a necessity that is reshaping the Shot Blasting Machine Market, as businesses seek to comply with stringent environmental regulations and meet consumer expectations for greener products.

Diverse Industry Applications

The versatility of shot blasting machines is a significant driver in the Shot Blasting Machine Market. These machines find applications across various sectors, including automotive, aerospace, construction, and metal fabrication. Each of these industries requires specific surface preparation techniques, which shot blasting can effectively provide. For example, in the automotive sector, shot blasting is essential for cleaning and preparing components for painting and coating. The increasing demand for high-quality surface finishes is propelling the adoption of shot blasting technology. Market analysis indicates that the automotive segment alone accounts for a substantial share of the shot blasting machine market, with expectations of continued growth as manufacturers seek to enhance product quality and durability. This diverse applicability underscores the importance of shot blasting machines in modern manufacturing processes.

Rising Demand for Surface Preparation

The Shot Blasting Machine Market is witnessing a surge in demand for effective surface preparation solutions. As industries increasingly prioritize product quality and durability, the need for efficient surface treatment methods has become paramount. Shot blasting is recognized for its ability to remove contaminants, rust, and old coatings, thereby preparing surfaces for subsequent treatments. This demand is particularly pronounced in sectors such as construction and manufacturing, where surface integrity is critical. Recent market data indicates that the surface preparation equipment segment is expected to grow significantly, driven by the need for enhanced performance and longevity of products. Consequently, the rising demand for surface preparation solutions is a key factor propelling the growth of the Shot Blasting Machine Market.

Increased Investment in Manufacturing Infrastructure

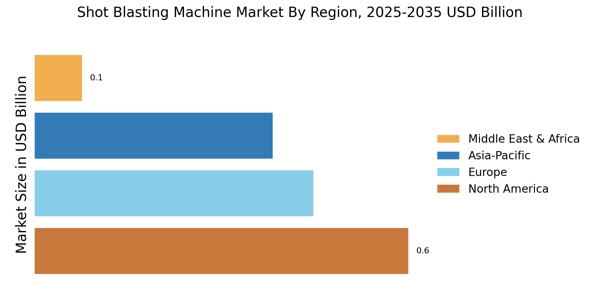

Investment in manufacturing infrastructure is a crucial driver for the Shot Blasting Machine Market. As countries focus on enhancing their industrial capabilities, there is a marked increase in the establishment of manufacturing facilities. This trend is particularly evident in emerging economies, where governments are incentivizing local production to boost economic growth. The establishment of new manufacturing plants often necessitates the procurement of advanced shot blasting machines to ensure efficient production processes. Furthermore, existing facilities are increasingly upgrading their equipment to remain competitive. Market forecasts suggest that this trend will continue, with substantial investments directed towards modernizing manufacturing infrastructure. This influx of capital is likely to stimulate demand for shot blasting machines, thereby contributing to the overall expansion of the Shot Blasting Machine Market.

Technological Advancements in Shot Blasting Machines

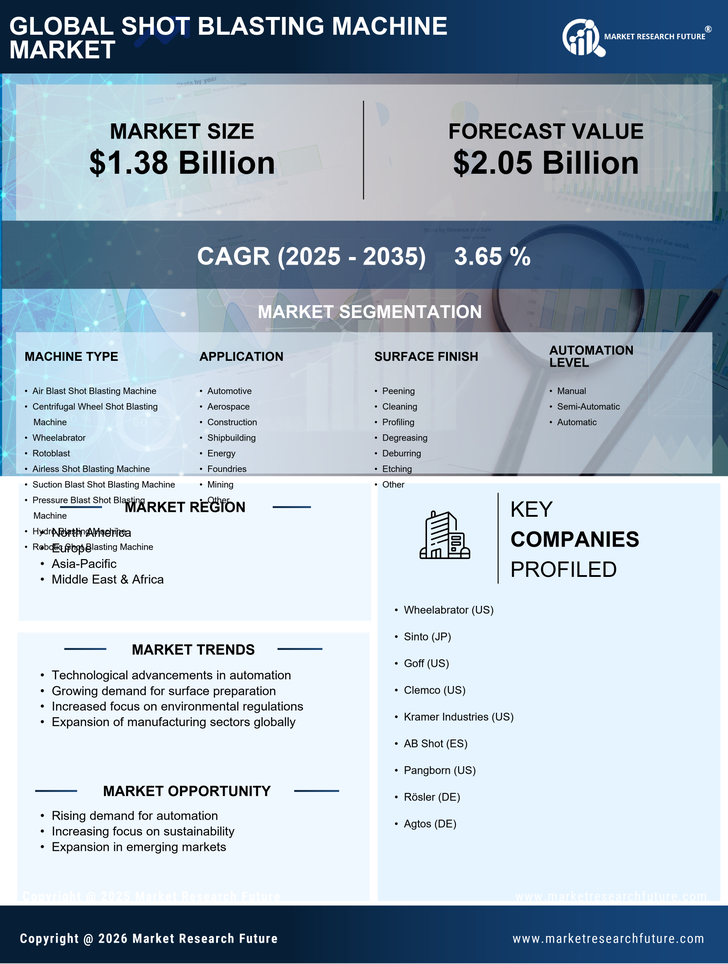

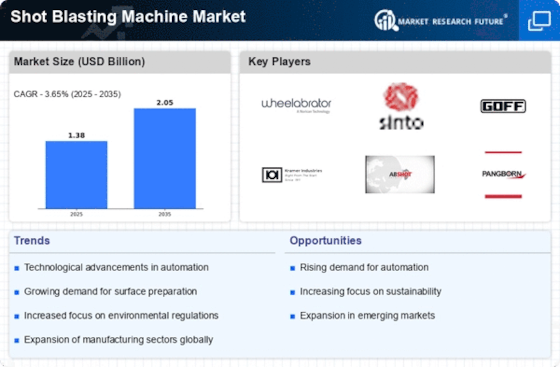

The Shot Blasting Machine Market is experiencing a notable transformation due to rapid technological advancements. Innovations such as automation and digitalization are enhancing the efficiency and precision of shot blasting processes. For instance, the integration of IoT technology allows for real-time monitoring and predictive maintenance, which can significantly reduce downtime. Furthermore, advancements in materials used for shot blasting media are improving the effectiveness of surface preparation. According to recent data, the market for automated shot blasting machines is projected to grow at a compound annual growth rate of approximately 6.5% over the next five years. This trend indicates a shift towards more sophisticated machinery that can cater to the evolving demands of various industries, including automotive and aerospace, thereby driving the overall growth of the Shot Blasting Machine Market.