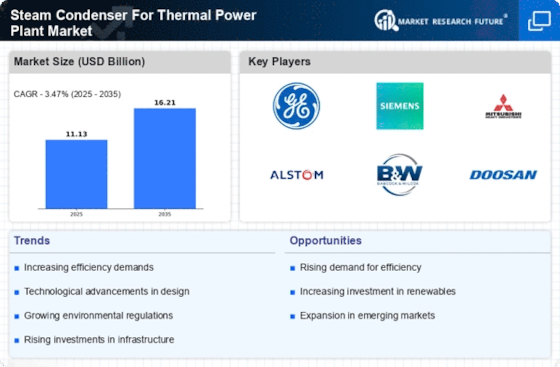

Increasing Energy Demand

The rising The Steam Condenser For Thermal Power Plant Industry. As populations grow and industrial activities expand, the need for efficient energy production intensifies. According to recent data, energy consumption is projected to increase by approximately 25% by 2040. This surge necessitates the construction and upgrading of thermal power plants, where steam condensers play a crucial role in enhancing efficiency and reducing emissions. The Steam Condenser For Thermal Power Plant Market is likely to benefit from this trend, as operators seek to optimize their systems to meet regulatory standards and consumer expectations. Furthermore, the shift towards cleaner energy sources may also drive investments in modern steam condenser technologies, which can improve overall plant performance.

Technological Innovations

Technological advancements are significantly influencing the Steam Condenser For Thermal Power Plant Market. Innovations in materials and design are leading to more efficient and durable condensers. For instance, the development of advanced heat exchanger technologies has improved thermal efficiency, which is essential for maximizing energy output. The market is witnessing a shift towards the use of corrosion-resistant materials, which enhance the lifespan of condensers and reduce maintenance costs. Additionally, the integration of smart technologies, such as IoT and predictive maintenance systems, is becoming more prevalent. These innovations not only improve operational efficiency but also align with the industry's push towards sustainability. As a result, the Steam Condenser For Thermal Power Plant Market is expected to see increased investments in research and development to further enhance these technologies.

Shift Towards Hybrid Energy Systems

The shift towards hybrid energy systems is emerging as a significant driver for the Steam Condenser For Thermal Power Plant Market. As the energy landscape evolves, there is a growing trend to integrate thermal power generation with renewable energy sources. This hybrid approach aims to enhance energy reliability and reduce dependence on fossil fuels. Steam condensers play a vital role in these systems by improving the efficiency of thermal plants, which can complement intermittent renewable sources like solar and wind. The market is likely to see increased demand for condensers that can operate effectively in hybrid setups, as operators seek to optimize performance and reduce operational costs. This transition not only supports energy diversification but also aligns with global sustainability goals, further propelling the Steam Condenser For Thermal Power Plant Market.

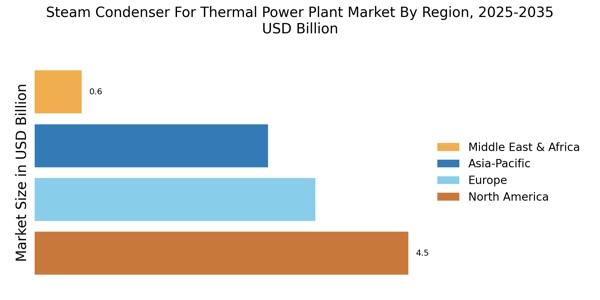

Investment in Infrastructure Development

Investment in infrastructure development is a crucial driver for the Steam Condenser For Thermal Power Plant Market. Many countries are focusing on upgrading their energy infrastructure to ensure reliable and efficient power generation. This trend is particularly evident in emerging economies, where rapid urbanization and industrialization are creating a pressing need for enhanced energy systems. According to estimates, investments in energy infrastructure are expected to reach trillions of dollars over the next decade. As thermal power plants undergo modernization, the demand for high-performance steam condensers will likely increase. These investments not only aim to improve energy efficiency but also to support the transition towards more sustainable energy practices. Therefore, the Steam Condenser For Thermal Power Plant Market stands to gain from this influx of capital aimed at infrastructure enhancement.

Regulatory Compliance and Environmental Standards

The Steam Condenser For Thermal Power Plant Market is significantly impacted by stringent regulatory compliance and environmental standards. Governments worldwide are implementing stricter emissions regulations to combat climate change and promote cleaner energy production. This regulatory landscape compels thermal power plants to adopt advanced steam condenser technologies that minimize environmental impact. For example, regulations may require reductions in greenhouse gas emissions, prompting operators to invest in more efficient condensers that enhance heat recovery and reduce waste. The market is likely to experience growth as companies strive to meet these evolving standards, which may also lead to increased collaboration between manufacturers and regulatory bodies. Consequently, the demand for innovative steam condenser solutions is expected to rise, driving market expansion.