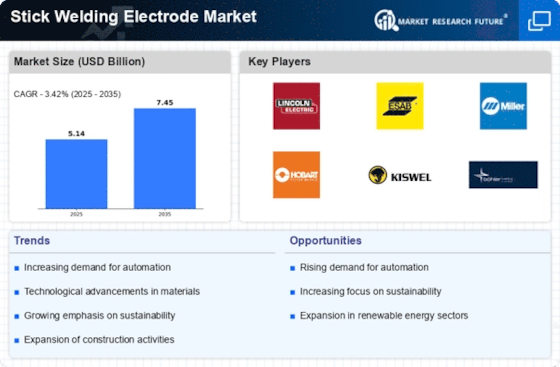

Rising Demand in Construction Sector

The Stick Welding Electrode Market is experiencing a notable surge in demand, primarily driven by the expansion of the construction sector. As urbanization accelerates, the need for robust infrastructure, including residential and commercial buildings, is increasing. This trend is reflected in the projected growth of the construction industry, which is expected to reach a valuation of several trillion dollars in the coming years. Stick welding electrodes are essential for various applications, including structural steel fabrication and repair work, making them indispensable in this sector. The increasing number of construction projects worldwide is likely to bolster the demand for stick welding electrodes, thereby enhancing the market's growth prospects.

Expansion of Automotive Manufacturing

The Stick Welding Electrode Market is poised for growth due to the expansion of automotive manufacturing. As the automotive sector evolves, there is an increasing need for high-quality welding solutions to meet stringent safety and performance standards. Stick welding electrodes are widely used in the production of vehicle frames and components, making them vital to the manufacturing process. Recent data indicates that the automotive industry is expected to grow significantly, with production levels projected to reach millions of units annually. This growth is likely to drive the demand for stick welding electrodes, as manufacturers seek reliable and efficient welding methods to enhance production capabilities.

Growing Adoption of Automation in Welding

The Stick Welding Electrode Market is witnessing a shift towards automation in welding processes. As industries seek to improve efficiency and reduce labor costs, the adoption of automated welding systems is becoming more prevalent. This trend is supported by research indicating that the automation market in manufacturing is expected to grow substantially in the coming years. Automated welding systems often require specific types of stick welding electrodes to optimize performance and ensure quality. Consequently, the increasing integration of automation in welding applications is likely to create new opportunities for the stick welding electrode market, as manufacturers adapt to these technological changes.

Increased Focus on Renewable Energy Projects

The Stick Welding Electrode Market is likely to benefit from the growing emphasis on renewable energy projects. As nations strive to meet sustainability goals, investments in renewable energy infrastructure, such as wind and solar farms, are on the rise. These projects often require extensive welding applications, where stick welding electrodes play a crucial role in ensuring structural integrity. The renewable energy sector is projected to witness substantial growth, with investments reaching hundreds of billions of dollars. This trend suggests a promising future for the stick welding electrode market, as the demand for reliable welding solutions in renewable energy applications continues to expand.

Technological Innovations in Welding Processes

Technological advancements in welding processes are significantly influencing the Stick Welding Electrode Market. Innovations such as the development of high-performance electrodes and automated welding systems are enhancing efficiency and productivity. For instance, the introduction of electrodes that can withstand higher temperatures and provide better arc stability is transforming welding practices. This evolution is supported by data indicating that the welding equipment market is projected to grow at a compound annual growth rate of over 5% in the next few years. As industries adopt these advanced technologies, the demand for specialized stick welding electrodes is expected to rise, further propelling market growth.