Sustainability and Eco-Friendly Practices

Sustainability is emerging as a vital driver for the Super Hard Material Market, as companies increasingly prioritize eco-friendly practices in their operations. The production of super hard materials is evolving to incorporate sustainable methods, such as recycling and the use of renewable resources. This shift is not only beneficial for the environment but also aligns with consumer preferences for sustainable products. Market data suggests that the demand for eco-friendly super hard materials is expected to rise by approximately 8% in the coming years, as industries seek to reduce their carbon footprint. This growing emphasis on sustainability is likely to reshape the Super Hard Material Market, encouraging innovation and the development of greener alternatives.

Technological Advancements in Manufacturing

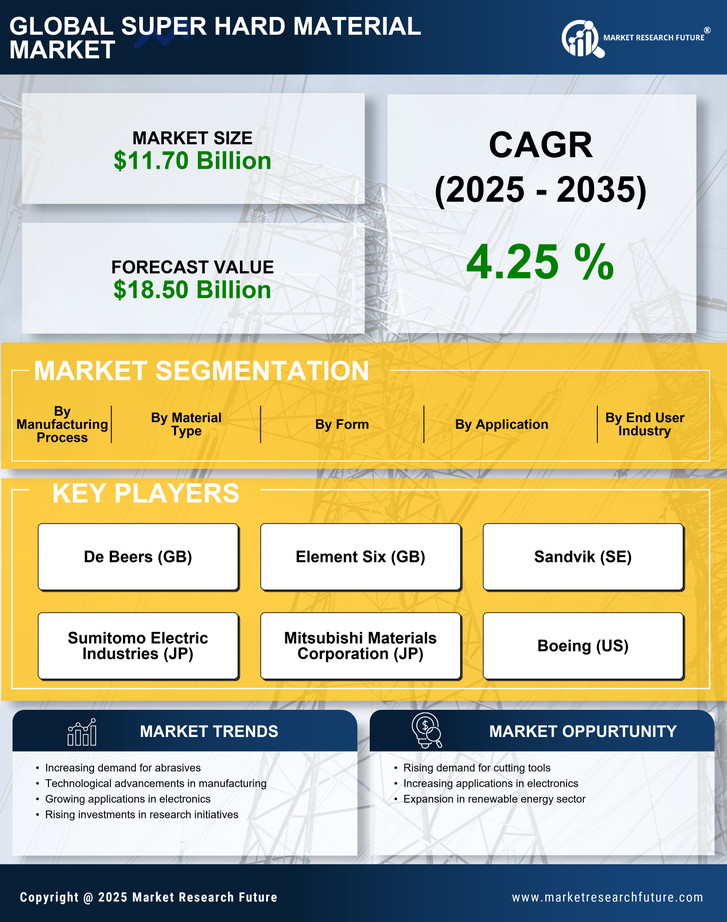

The Super Hard Material Market is experiencing a surge in technological advancements that enhance the production and application of super hard materials. Innovations in manufacturing processes, such as improved sintering techniques and advanced coating technologies, are enabling the creation of materials with superior hardness and durability. For instance, the introduction of high-pressure high-temperature (HPHT) synthesis methods has led to the development of synthetic diamonds that exhibit exceptional performance in various applications. This trend is reflected in the market data, which indicates a projected growth rate of approximately 6% annually in the super hard materials segment, driven by these technological improvements. As industries increasingly adopt these advanced materials for cutting, grinding, and drilling applications, the Super Hard Material Market is poised for significant expansion.

Increased Investment in Research and Development

Investment in research and development (R&D) is a crucial driver for the Super Hard Material Market, as companies strive to innovate and improve material properties. Enhanced R&D efforts are leading to the discovery of new super hard materials and the optimization of existing ones, which can significantly impact various applications, including mining, construction, and manufacturing. Recent data indicates that R&D spending in the super hard materials sector has increased by approximately 10% over the past year, reflecting a commitment to advancing material science. This focus on innovation not only fosters the development of superior products but also positions the Super Hard Material Market to meet the evolving needs of diverse industries, ensuring sustained growth and competitiveness.

Rising Demand in Aerospace and Automotive Sectors

The aerospace and automotive sectors are pivotal drivers of the Super Hard Material Market, as these industries increasingly require materials that can withstand extreme conditions. The demand for super hard materials, such as cubic boron nitride and synthetic diamonds, is growing due to their ability to enhance the performance and longevity of components. Market data suggests that the aerospace sector alone is expected to contribute significantly to the overall market growth, with an estimated increase of 7% in the use of super hard materials for engine components and cutting tools. This rising demand is indicative of a broader trend where manufacturers seek to improve efficiency and reduce maintenance costs, thereby propelling the Super Hard Material Market forward.

Growing Applications in Electronics and Telecommunications

The Super Hard Material Market is witnessing a growing demand for super hard materials in the electronics and telecommunications sectors. As technology advances, the need for materials that can withstand wear and tear while maintaining performance is becoming increasingly critical. Super hard materials, such as diamond-like carbon coatings, are being utilized in various electronic components to enhance durability and efficiency. Market analysis indicates that the electronics sector is projected to account for a significant share of the super hard materials market, with an expected growth rate of around 5% annually. This trend underscores the importance of super hard materials in ensuring the reliability and longevity of electronic devices, thereby driving the Super Hard Material Market forward.