Expansion of Aerospace Applications

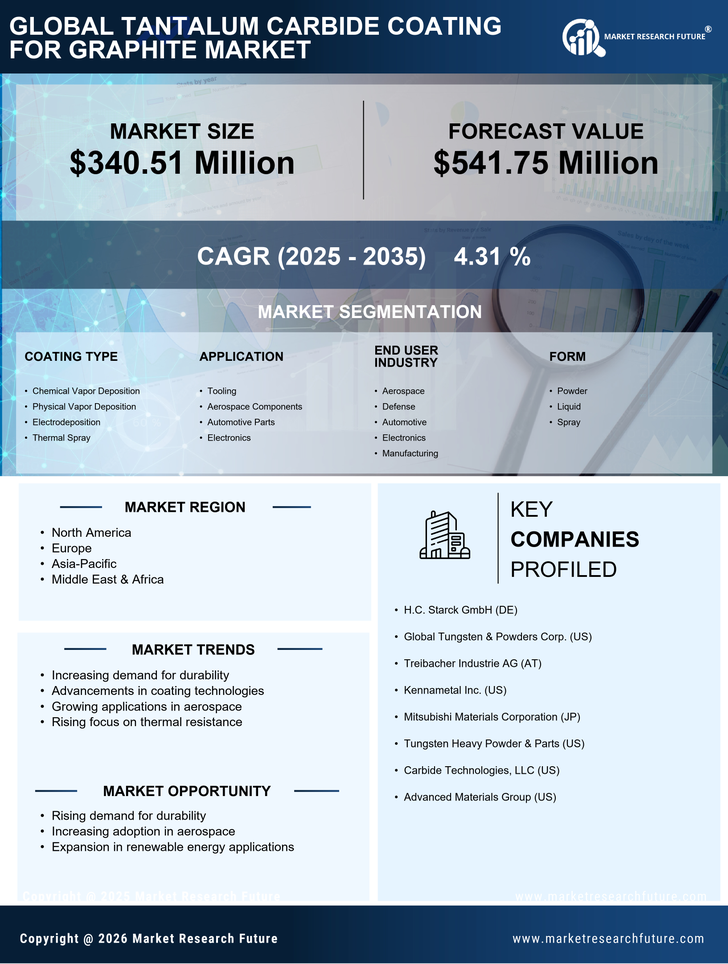

The Tantalum Carbide Coating For Graphite Market is experiencing expansion due to the growing applications in the aerospace sector. Tantalum carbide coatings are recognized for their ability to withstand high temperatures and corrosive environments, making them suitable for critical aerospace components. The aerospace industry is projected to grow at a compound annual growth rate of around 4.5% through 2030, driven by increasing air travel and advancements in aircraft technology. As manufacturers strive to enhance the performance and safety of aircraft, the adoption of tantalum carbide coatings is likely to increase, thereby contributing to the growth of the Tantalum Carbide Coating For Graphite Market.

Growth in Energy Sector Applications

The Tantalum Carbide Coating For Graphite Market is poised for growth due to the increasing applications in the energy sector, particularly in renewable energy technologies. As the world shifts towards sustainable energy solutions, the demand for materials that can withstand extreme conditions is rising. Tantalum carbide coatings are being utilized in various energy applications, including wind turbine components and solar panel manufacturing. The energy sector is projected to grow significantly, with investments in renewable energy expected to exceed USD 2 trillion by 2030. This growth is likely to drive the adoption of tantalum carbide coatings, as they offer enhanced durability and efficiency, thereby supporting the expansion of the Tantalum Carbide Coating For Graphite Market.

Rising Adoption in Defense Applications

The Tantalum Carbide Coating For Graphite Market is witnessing increased adoption in defense applications, where the need for high-performance materials is critical. Tantalum carbide coatings are favored for their exceptional hardness and resistance to corrosion, making them ideal for military equipment and components. The defense sector is expected to see a compound annual growth rate of approximately 3.5% through 2030, driven by rising geopolitical tensions and the need for advanced weaponry. As defense contractors seek to enhance the performance and reliability of their products, the integration of tantalum carbide coatings is likely to become more prevalent, thereby bolstering the Tantalum Carbide Coating For Graphite Market.

Increasing Demand in Semiconductor Industry

The Tantalum Carbide Coating For Graphite Market is experiencing a notable surge in demand driven by the semiconductor sector. As the need for advanced materials in semiconductor manufacturing escalates, tantalum carbide coatings are increasingly recognized for their superior thermal and electrical properties. This trend is underscored by the projected growth of the semiconductor market, which is expected to reach USD 1 trillion by 2030. The unique characteristics of tantalum carbide coatings, such as their hardness and resistance to wear, make them particularly suitable for applications in semiconductor fabrication equipment. Consequently, the integration of these coatings is likely to enhance the performance and longevity of critical components, thereby propelling the Tantalum Carbide Coating For Graphite Market forward.

Technological Advancements in Coating Processes

The Tantalum Carbide Coating For Graphite Market is benefiting from ongoing technological advancements in coating processes. Innovations such as physical vapor deposition and chemical vapor deposition are enhancing the efficiency and effectiveness of tantalum carbide coatings. These advancements allow for better control over coating thickness and uniformity, which are crucial for achieving optimal performance in various applications. As industries increasingly prioritize precision and quality, the demand for advanced coating technologies is expected to rise. This trend is likely to drive the growth of the Tantalum Carbide Coating For Graphite Market, as manufacturers seek to leverage these technologies to improve product performance and durability.