Regulatory Compliance

Regulatory compliance is increasingly influencing the Textile Pretreatment Chemicals Market, as governments worldwide implement stricter environmental and safety standards. Manufacturers are required to adhere to these regulations, which often necessitates the use of compliant pretreatment chemicals. This compliance not only mitigates legal risks but also enhances product safety and quality. The market is witnessing a shift towards chemicals that meet these stringent regulations, which could potentially lead to a market expansion of around 4% in the coming years. As companies invest in compliant solutions, the demand for innovative and safe pretreatment chemicals is likely to rise, thereby shaping the future landscape of the Textile Pretreatment Chemicals Market.

Sustainability Initiatives

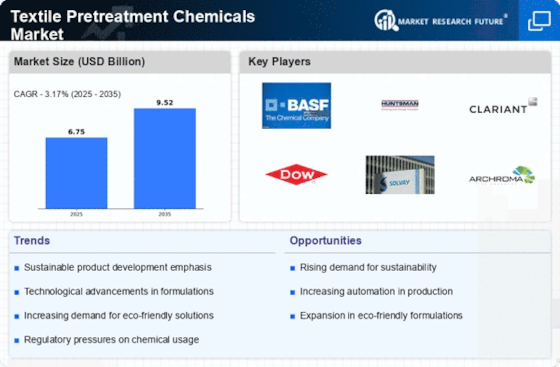

The increasing emphasis on sustainability within the textile industry appears to be a pivotal driver for the Textile Pretreatment Chemicals Market. Manufacturers are increasingly adopting eco-friendly pretreatment chemicals to align with environmental regulations and consumer preferences. This shift is evidenced by a growing demand for biodegradable and non-toxic chemicals, which are projected to capture a significant market share. As sustainability becomes a core value for brands, the market for textile pretreatment chemicals is likely to expand, with estimates suggesting a compound annual growth rate of around 5% over the next few years. This trend not only enhances brand reputation but also meets the rising consumer demand for sustainable products, thereby propelling the Textile Pretreatment Chemicals Market forward.

Technological Advancements

Technological advancements in textile processing are driving innovation within the Textile Pretreatment Chemicals Market. The integration of automation and digital technologies has led to the development of more efficient pretreatment processes, reducing water and energy consumption. For instance, the adoption of advanced formulations and application techniques has improved the effectiveness of pretreatment chemicals, resulting in higher quality outputs. Market data indicates that the use of innovative technologies could enhance production efficiency by up to 30%, thereby attracting investments in the sector. As manufacturers seek to optimize their operations, the demand for technologically advanced pretreatment chemicals is expected to rise, further stimulating growth in the Textile Pretreatment Chemicals Market.

Customization and Specialization

The trend towards customization and specialization in textile production is emerging as a significant driver for the Textile Pretreatment Chemicals Market. As brands strive to differentiate their products, there is a growing need for specialized pretreatment chemicals tailored to specific fabric types and end-use applications. This demand for customized solutions is likely to lead to the development of niche products that cater to unique market segments. Market analysis suggests that the segment for specialized pretreatment chemicals could witness a growth rate of approximately 6% annually, reflecting the industry's shift towards more personalized offerings. Consequently, manufacturers are compelled to innovate and diversify their product lines, thereby enhancing the overall competitiveness of the Textile Pretreatment Chemicals Market.

Rising Demand for Functional Textiles

The rising demand for functional textiles is a notable driver for the Textile Pretreatment Chemicals Market. As consumers increasingly seek textiles with enhanced properties such as moisture-wicking, stain resistance, and UV protection, the need for specialized pretreatment chemicals becomes apparent. These chemicals play a crucial role in imparting desired functionalities to fabrics, thereby meeting consumer expectations. Market projections indicate that the functional textiles segment could grow at a rate of approximately 7% annually, driven by trends in activewear and home textiles. This surge in demand for functional textiles is likely to propel the Textile Pretreatment Chemicals Market, as manufacturers strive to innovate and develop new chemical formulations that cater to these evolving consumer needs.