Titanium Sponge For Aerospace & Defense Market Summary

As per MRFR analysis, the Titanium Sponge for Aerospace and Defense Market was estimated at 3.727 USD Billion in 2024. The Titanium Sponge industry is projected to grow from 3.908 USD Billion in 2025 to 6.295 USD Billion by 2035, exhibiting a compound annual growth rate (CAGR) of 4.88 during the forecast period 2025 - 2035.

Key Market Trends & Highlights

The Titanium Sponge for Aerospace and Defense Market is poised for growth driven by technological advancements and sustainability initiatives.

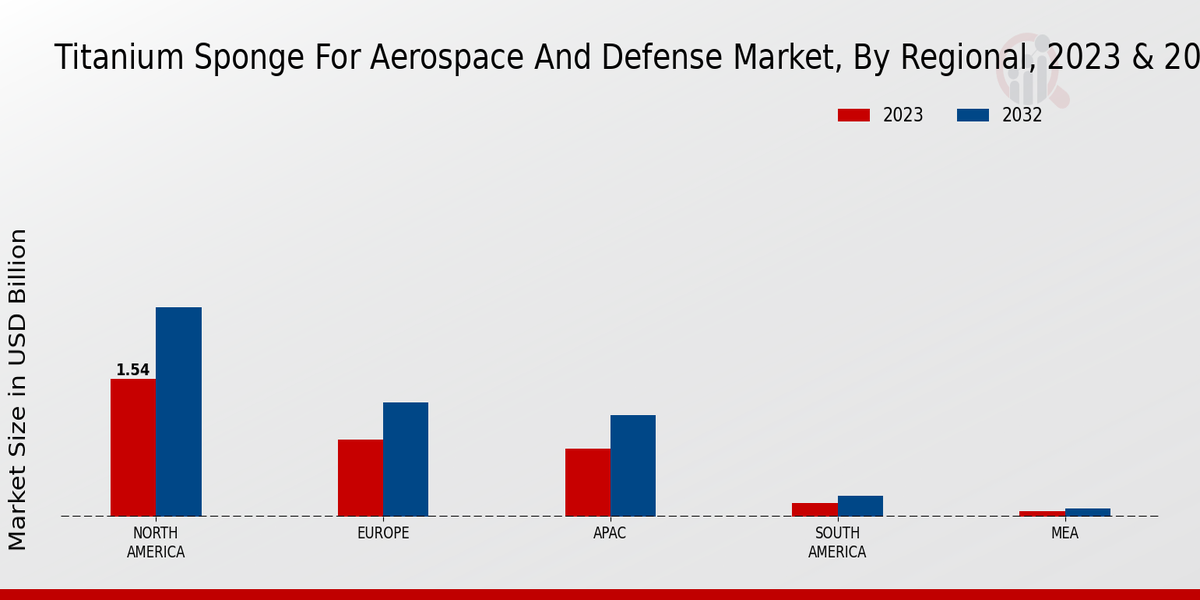

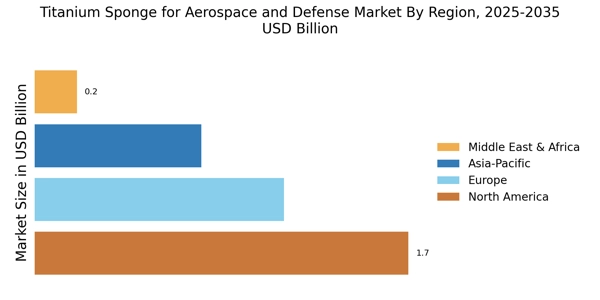

- North America remains the largest market for titanium sponge, primarily due to its robust aerospace and defense sectors.

- Asia-Pacific is emerging as the fastest-growing region, fueled by increasing investments in military capabilities and commercial aviation.

- The aircraft manufacturing segment dominates the market, while the missile manufacturing segment is experiencing rapid growth.

- Rising demand for lightweight materials and increased military expenditure are key drivers propelling market expansion.

Market Size & Forecast

| 2024 Market Size | 3.727 (USD Billion) |

| 2035 Market Size | 6.295 (USD Billion) |

| CAGR (2025 - 2035) | 4.88% |

Major Players

Titanium Metals Corporation (US), Allegheny Technologies Incorporated (US), VSMPO-AVISMA Corporation (RU), Kobe Steel, Ltd. (JP), RTI International Metals, Inc. (US), Timet (US), Haynes International, Inc. (US), Aerospace Alloys, Inc. (US)

Leave a Comment