Emergence of Advanced Materials

The abrasive waterjet-cutting-machine market is poised for growth due to the emergence of advanced materials, such as composites and high-strength alloys. These materials, increasingly used in industries like aerospace and automotive, require specialized cutting techniques that traditional methods may not effectively handle. The versatility of abrasive waterjet cutting machines allows for the precise cutting of these complex materials without compromising their structural integrity. As the demand for advanced materials continues to rise, the market is likely to expand, with manufacturers investing in cutting technologies that can accommodate these innovations. This trend suggests a promising future for the abrasive waterjet-cutting-machine market.

Rising Demand for Precision Cutting

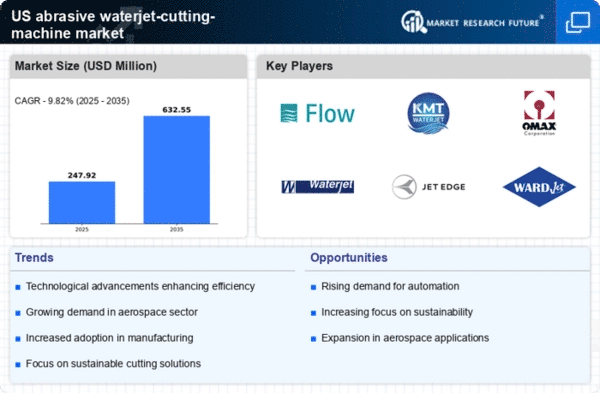

The abrasive waterjet-cutting-machine market experiences a notable surge in demand for precision cutting across various industries, including aerospace, automotive, and manufacturing. This demand is driven by the need for intricate designs and high-quality finishes, which traditional cutting methods often fail to achieve. In 2025, the market is projected to grow at a CAGR of approximately 6.5%, reflecting the increasing reliance on advanced cutting technologies. As industries prioritize accuracy and efficiency, the adoption of abrasive waterjet cutting machines is likely to expand, further solidifying their role in modern manufacturing processes.

Growth in Automation and Industry 4.0

The integration of automation and Industry 4.0 principles significantly influences the abrasive waterjet-cutting-machine market. As manufacturers seek to enhance productivity and reduce operational costs, the incorporation of automated systems into cutting processes becomes essential. This trend is expected to drive the market, with automation potentially increasing production efficiency by up to 30%. Furthermore, the ability to integrate these machines with smart technologies allows for real-time monitoring and adjustments, which can lead to improved quality control and reduced waste. Consequently, the market is likely to see a shift towards more automated solutions in the coming years.

Expansion of the Metal Fabrication Sector

The abrasive waterjet-cutting-machine market benefits from the ongoing expansion of the metal fabrication sector in the United States. As industries such as construction, shipbuilding, and heavy machinery continue to grow, the demand for efficient and versatile cutting solutions rises. In 2025, the metal fabrication industry is anticipated to reach a valuation of over $100 billion, creating a substantial opportunity for abrasive waterjet cutting technologies. These machines offer the ability to cut various materials, including metals, composites, and ceramics, making them indispensable in a diverse range of applications. This growth in metal fabrication is likely to bolster the market significantly.

Increased Focus on Safety and Environmental Regulations

The abrasive waterjet-cutting-machine market is increasingly shaped by stringent safety and environmental regulations. As industries face pressure to comply with regulations regarding emissions and workplace safety, the adoption of waterjet cutting technology, which produces minimal waste and noise, becomes more appealing. The machines operate without generating hazardous fumes, aligning with the growing emphasis on sustainable practices. This shift is likely to enhance market growth, as companies seek to invest in technologies that not only meet regulatory standards but also promote a safer working environment. The market may see a rise in demand for machines that comply with these evolving regulations.