Advancements in Material Science

Innovations in material science are propelling the automated 3d-printing market forward. The development of new materials, such as high-performance polymers and metal alloys, expands the range of applications for 3D printing. In 2025, the market for advanced materials in 3D printing is expected to grow by approximately 20%, driven by industries such as aerospace, automotive, and healthcare. These advancements enable the production of stronger, lighter, and more durable components, which are essential for meeting the rigorous demands of modern engineering. As material options continue to diversify, the automated 3d-printing market is likely to attract a broader customer base seeking innovative solutions.

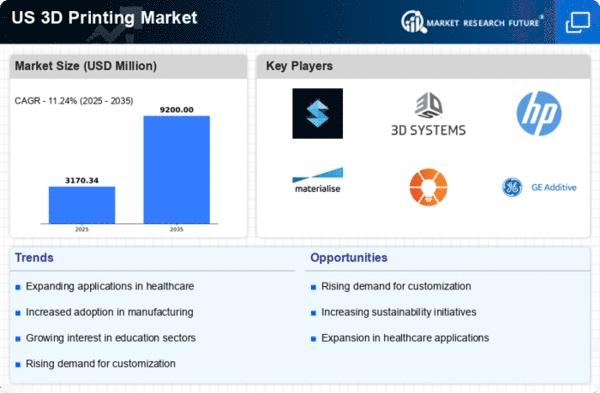

Increased Adoption in Healthcare

The healthcare sector is increasingly recognizing the potential of the automated 3d-printing market for applications such as custom implants, prosthetics, and surgical models. The ability to create patient-specific solutions enhances treatment outcomes and reduces surgery times. In 2025, the market for 3D-printed medical devices is projected to exceed $1 billion, reflecting a compound annual growth rate of around 25%. This growth is fueled by advancements in biocompatible materials and regulatory approvals for 3D-printed products. As healthcare providers seek to improve patient care and operational efficiency, the automated 3d-printing market is poised to become an integral part of medical innovation.

Cost Efficiency and Material Savings

Cost efficiency remains a pivotal driver in the automated 3d-printing market. The technology allows for significant reductions in material waste, as it utilizes only the necessary amount of material to create parts. This efficiency can lead to savings of up to 30% in material costs compared to traditional manufacturing methods. Furthermore, the ability to produce components on-demand reduces inventory costs and storage needs. As manufacturers strive to optimize their operations and improve profit margins, the automated 3d-printing market is likely to see increased adoption, particularly among small to medium-sized enterprises looking to leverage these financial benefits.

Rising Demand for Prototyping Solutions

The automated 3d-printing market is experiencing a surge in demand for rapid prototyping solutions across various industries. Companies are increasingly adopting 3D printing technologies to accelerate product development cycles, reduce costs, and enhance design flexibility. In 2025, the market for prototyping services is projected to reach approximately $2 billion, reflecting a growth rate of around 15% annually. This trend is driven by the need for faster time-to-market and the ability to create complex geometries that traditional manufacturing methods cannot achieve. As businesses seek to innovate and remain competitive, the automated 3d-printing market is positioned to play a crucial role in facilitating these advancements.

Government Support and Funding Initiatives

Government support plays a crucial role in the growth of the automated 3d-printing market. Various federal and state initiatives are aimed at promoting research and development in additive manufacturing technologies. Funding programs and grants are being allocated to encourage innovation and collaboration between industry and academia. In 2025, it is estimated that government investments in 3D printing technologies could reach $500 million, fostering advancements in manufacturing processes and workforce development. This support not only enhances the competitiveness of the automated 3d-printing market but also ensures that the U.S. remains at the forefront of technological advancements in this field.