Increased Focus on Safety Standards

Safety regulations in industrial environments are becoming more stringent, which is positively impacting the bench hydraulic-press market. The Occupational Safety and Health Administration (OSHA) has implemented various guidelines to ensure worker safety, leading to a heightened demand for equipment that meets these standards. Manufacturers are now prioritizing the acquisition of hydraulic presses that incorporate advanced safety features, such as automatic shut-off mechanisms and enhanced guarding systems. This shift not only ensures compliance with regulations but also minimizes the risk of workplace accidents. As a result, the bench hydraulic-press market is likely to see an increase in sales of safety-compliant models, reflecting a broader trend towards safer industrial practices.

Rising Demand in Manufacturing Sectors

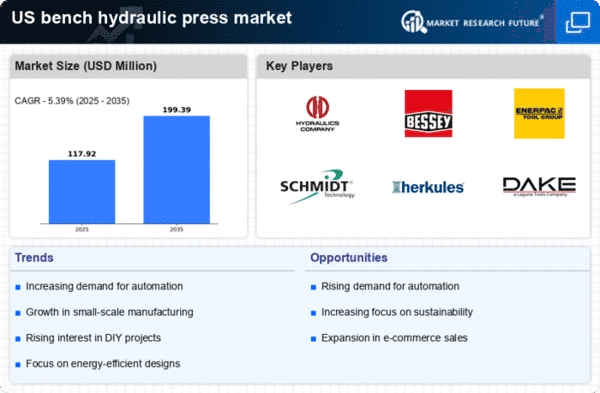

The bench hydraulic-press market is experiencing a notable surge in demand, particularly from manufacturing. Industries such as automotive, aerospace, and metal fabrication are increasingly relying on hydraulic presses for their production processes. This trend is driven by the need for precision and efficiency in manufacturing operations. According to recent data, the manufacturing sector in the US is projected to grow at a CAGR of approximately 3.5% over the next five years. This growth is likely to bolster the bench hydraulic-press market, as manufacturers seek advanced equipment to enhance productivity and reduce operational costs. The increasing complexity of manufacturing processes necessitates the adoption of versatile and reliable hydraulic presses, further propelling market growth.

Technological Integration in Equipment

The integration of advanced technologies into hydraulic press systems transforms the bench hydraulic-press market. Innovations such as IoT connectivity, automation, and data analytics are enabling manufacturers to optimize their operations and enhance productivity. For instance, hydraulic presses equipped with smart sensors can monitor performance in real-time, allowing for predictive maintenance and reduced downtime. This technological evolution is appealing to manufacturers looking to streamline their processes and improve efficiency. As the trend towards automation continues, the bench hydraulic-press market is likely to witness increased adoption of technologically advanced models, catering to the evolving needs of modern manufacturing.

Growth of Small and Medium Enterprises (SMEs)

The bench hydraulic-press market is benefiting from the growth of small and medium enterprises (SMEs) across various sectors. SMEs are increasingly investing in hydraulic presses to enhance their production capabilities and improve operational efficiency. This trend is particularly evident in industries such as woodworking, metalworking, and crafts, where smaller businesses are seeking affordable yet effective hydraulic solutions. The US Small Business Administration reports that SMEs account for approximately 99.9% of all US businesses, indicating a substantial market potential for bench hydraulic presses. As these enterprises continue to expand, the demand for compact and versatile hydraulic presses is expected to rise, further driving market growth.

Expansion of E-commerce and Online Sales Channels

The bench hydraulic-press market is experiencing a shift due to the expansion of e-commerce and online sales channels. Manufacturers and suppliers are increasingly leveraging digital platforms to reach a broader customer base, facilitating easier access to hydraulic press products. This trend is particularly beneficial for small businesses and individual craftsmen who may not have the resources to visit physical stores. According to recent statistics, online retail sales in the US are projected to grow by approximately 15% annually. This growth in e-commerce is likely to enhance the visibility and availability of bench hydraulic presses, driving market growth as consumers seek convenient purchasing options.