Emergence of Advanced Materials

The Hydraulic Press Machine Market is being shaped by the emergence of advanced materials, which require specialized processing techniques. Industries are increasingly utilizing materials such as composites and high-strength alloys, which necessitate the use of hydraulic presses for effective shaping and forming. The demand for these advanced materials is projected to grow, driven by their applications in aerospace, construction, and consumer goods. As manufacturers adapt to these changes, the need for hydraulic presses that can handle diverse materials and complex shapes becomes paramount. This trend suggests that the Hydraulic Press Machine Market will likely see an increase in demand for machines equipped with advanced features to accommodate the processing of innovative materials, thereby enhancing their competitive edge in various sectors.

Expansion of Automotive Industry

The Hydraulic Press Machine Market is significantly impacted by the expansion of the automotive industry, which relies heavily on hydraulic presses for various manufacturing processes. The automotive sector is projected to grow at a steady pace, driven by increasing consumer demand for vehicles and advancements in electric vehicle technology. Hydraulic presses are essential for tasks such as stamping, forming, and assembling automotive components. Data indicates that the automotive industry is expected to reach USD 5 trillion by 2026, further fueling the demand for hydraulic presses. As manufacturers seek to optimize production processes and enhance product quality, the Hydraulic Press Machine Market is likely to benefit from this growth, as hydraulic presses become integral to meeting the evolving needs of the automotive sector.

Growing Focus on Energy Efficiency

The Hydraulic Press Machine Market is increasingly influenced by a growing focus on energy efficiency and sustainability. As industries strive to reduce their carbon footprint and comply with stringent environmental regulations, energy-efficient hydraulic presses are gaining traction. Recent studies suggest that energy-efficient hydraulic systems can reduce energy consumption by up to 30%, making them an attractive option for manufacturers. This shift towards energy-efficient solutions is not only beneficial for the environment but also leads to significant cost savings for businesses. As a result, manufacturers are more inclined to invest in hydraulic presses that offer enhanced energy efficiency. The Hydraulic Press Machine Market is thus likely to see a rise in demand for machines that incorporate advanced technologies aimed at reducing energy consumption while maintaining high performance levels.

Increased Investment in Automation

The Hydraulic Press Machine Market is witnessing increased investment in automation technologies, which is reshaping the landscape of industrial operations. Companies are increasingly adopting automated solutions to improve efficiency and reduce labor costs. Hydraulic presses, known for their precision and reliability, are being integrated into automated production lines. This trend is supported by data indicating that the automation market is expected to reach USD 300 billion by 2026, with hydraulic presses playing a crucial role in this transformation. The integration of advanced control systems and robotics with hydraulic presses enhances their functionality, allowing for higher production rates and improved product quality. Consequently, the Hydraulic Press Machine Market is likely to benefit from this shift towards automation, as manufacturers seek to leverage technology to remain competitive in a rapidly evolving market.

Rising Demand in Manufacturing Sector

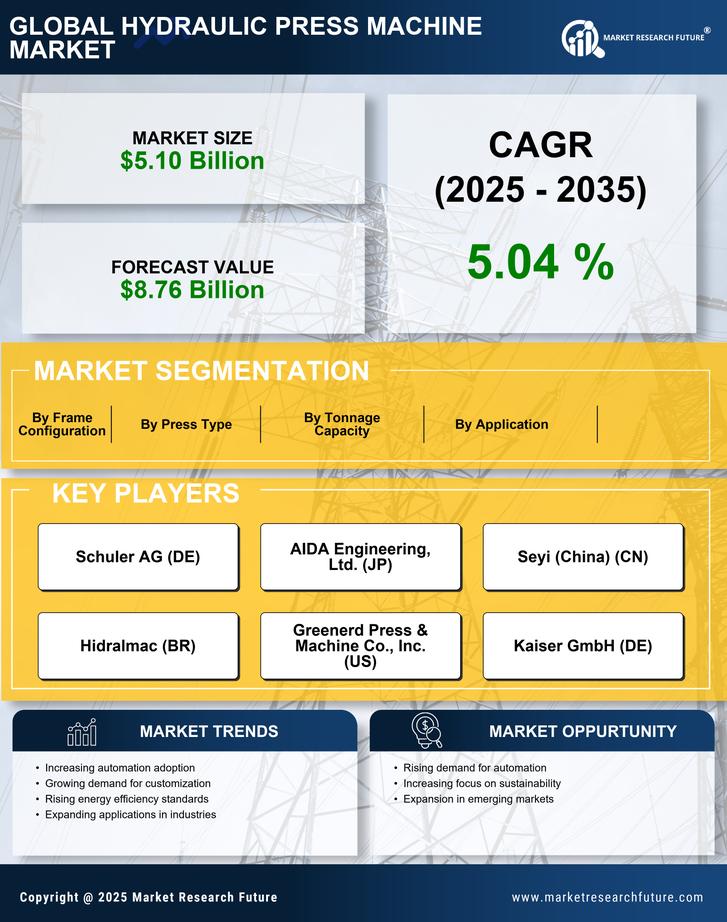

The Hydraulic Press Machine Market is experiencing a notable surge in demand, particularly within the manufacturing sector. As industries increasingly focus on automation and efficiency, hydraulic presses are becoming essential for various applications, including metal forming, plastic molding, and assembly processes. According to recent data, the manufacturing sector is projected to grow at a compound annual growth rate of approximately 4.5% over the next five years. This growth is likely to drive the demand for hydraulic press machines, as manufacturers seek to enhance productivity and reduce operational costs. Furthermore, the versatility of hydraulic presses allows for their use in diverse applications, making them indispensable in modern manufacturing environments. As a result, the Hydraulic Press Machine Market is poised for significant expansion, driven by the evolving needs of the manufacturing landscape.