Increased Focus on Automation

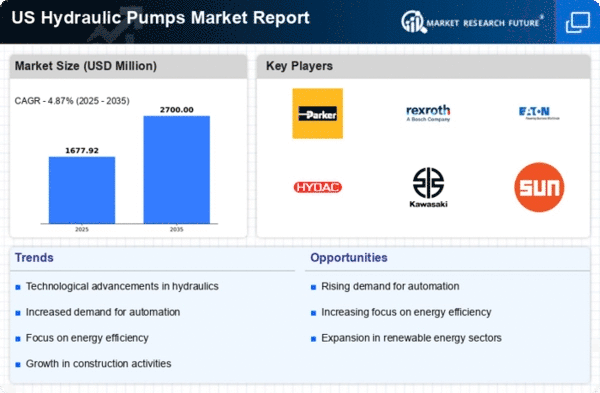

Automation in industrial processes is becoming a focal point for many sectors in the US, which could significantly impact the hydraulic pumps market. As manufacturers strive for greater efficiency and reduced operational costs, the integration of automated systems is on the rise. Hydraulic pumps play a crucial role in automated machinery, providing the necessary power for various applications. The hydraulic pumps market is expected to see a surge in demand as industries adopt automation technologies, potentially leading to a market growth rate of around 6% by 2026. This trend indicates a shift towards more sophisticated hydraulic solutions that can seamlessly integrate with automated systems.

Growth in Agricultural Mechanization

The agricultural sector in the US is increasingly adopting mechanization to enhance productivity, which appears to be a significant driver for the hydraulic pumps market. As farmers seek to improve efficiency and reduce labor costs, hydraulic systems are becoming integral to modern farming equipment. The hydraulic pumps market is projected to grow by about 5% as more agricultural machinery, such as tractors and harvesters, incorporate hydraulic technology. This trend suggests a shift towards more advanced hydraulic solutions that can meet the demands of contemporary agriculture, ultimately leading to improved crop yields and operational efficiency.

Rising Demand in Construction Sector

The construction sector in the US is experiencing a notable resurgence, which appears to be a primary driver for the hydraulic pumps market. As infrastructure projects gain momentum, the need for efficient hydraulic systems becomes increasingly critical. In 2025, the construction industry is projected to grow by approximately 5% annually, leading to heightened demand for hydraulic pumps. These pumps are essential for various applications, including excavation, lifting, and material handling. The hydraulic pumps market is likely to benefit from this trend, as construction companies seek reliable and powerful hydraulic solutions to enhance productivity and efficiency on job sites.

Expansion of Renewable Energy Projects

The push for renewable energy sources in the US is likely to drive growth in the hydraulic pumps market. As wind and solar energy projects expand, the need for hydraulic systems to support these initiatives becomes apparent. Hydraulic pumps are utilized in various applications within renewable energy, such as in the operation of wind turbines and solar tracking systems. The hydraulic pumps market may witness a growth rate of approximately 7% as investments in renewable energy infrastructure increase. This trend not only supports environmental goals but also creates opportunities for hydraulic pump manufacturers to innovate and provide tailored solutions for the energy sector.

Regulatory Compliance and Safety Standards

The hydraulic pumps market is also influenced by the evolving regulatory landscape in the US, particularly concerning safety and environmental standards. As industries face stricter regulations, the demand for hydraulic pumps that comply with these standards is likely to increase. Manufacturers are compelled to innovate and produce hydraulic systems that not only meet performance criteria but also adhere to safety protocols. The hydraulic pumps market may experience a growth rate of around 4% as companies invest in compliant technologies. This trend underscores the importance of safety and environmental considerations in the design and production of hydraulic pumps.