Hydraulic Gear Pump Market Summary

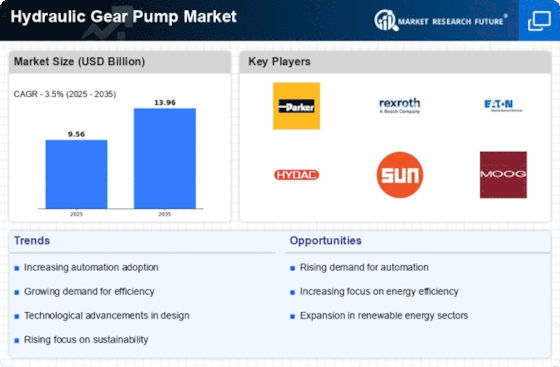

As per Market Research Future analysis, the Hydraulic Gear Pump Market Size was estimated at 9.56 USD Billion in 2024. The Hydraulic Gear Pump industry is projected to grow from 9.895 USD Billion in 2025 to 13.96 USD Billion by 2035, exhibiting a compound annual growth rate (CAGR) of 3.5% during the forecast period 2025 - 2035

Key Market Trends & Highlights

The Hydraulic Gear Pump Market is poised for substantial growth driven by technological advancements and increasing demand across various sectors.

- Technological advancements are enhancing the efficiency and performance of hydraulic gear pumps, particularly in North America.

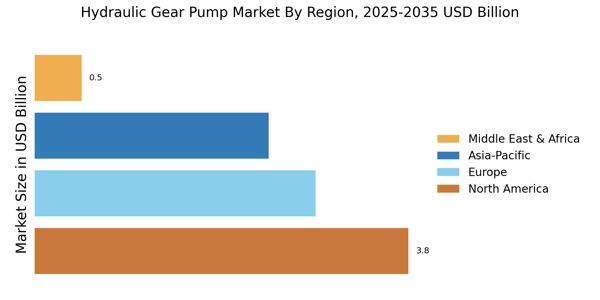

- The Asia-Pacific region is experiencing rapid growth, driven by industrial expansion and rising infrastructure investments.

- External gear pumps remain the largest segment, while internal gear pumps are emerging as the fastest-growing segment in the market.

- Key market drivers include the rising demand in the construction sector and the growing focus on energy efficiency.

Market Size & Forecast

| 2024 Market Size | 9.56 (USD Billion) |

| 2035 Market Size | 13.96 (USD Billion) |

| CAGR (2025 - 2035) | 3.5% |

Major Players

Parker Hannifin (US), Bosch Rexroth (DE), Eaton (US), Hydac (DE), Sun Hydraulics (US), Moog (US), Kawasaki (JP), Danfoss (DK), Bucher Hydraulics (DE)