Enhanced Safety Protocols

Safety remains a paramount concern in the manufacturing sector, and the immersive technology-in-manufacturing market is poised to address this issue effectively. By utilizing VR and AR, manufacturers can create realistic training environments that simulate hazardous situations without exposing employees to real danger. This approach not only enhances safety training but also reduces the likelihood of workplace accidents. Data suggests that companies implementing immersive safety training programs have seen a reduction in incident rates by up to 30%. As safety regulations become increasingly stringent, the adoption of immersive technologies for training and safety compliance is likely to grow. This trend indicates a significant opportunity for the immersive technology-in-manufacturing market, as organizations prioritize employee safety while optimizing training processes.

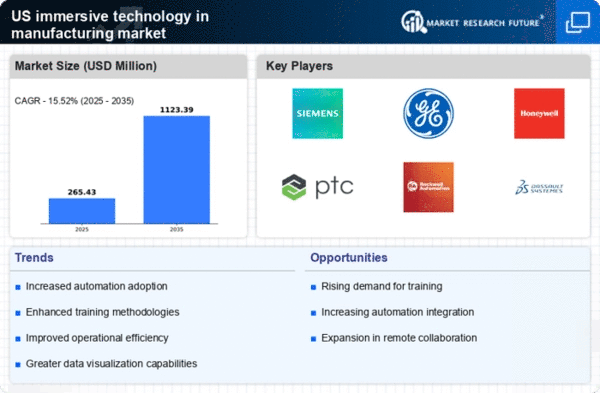

Increased Demand for Automation

The immersive technology-in-manufacturing market is experiencing a surge in demand for automation solutions. As manufacturers strive to enhance productivity and reduce operational costs, immersive technologies such as virtual reality (VR) and augmented reality (AR) are being integrated into production processes. According to recent data, the automation sector is projected to grow at a CAGR of 10.5% through 2027, indicating a strong inclination towards automated systems. This trend is likely to drive investments in immersive technologies, as they facilitate real-time monitoring and control of manufacturing operations. Furthermore, the ability to simulate complex manufacturing scenarios using immersive technology enhances decision-making processes, thereby improving overall efficiency. Consequently, the increasing demand for automation is a pivotal driver for the immersive technology-in-manufacturing market, as companies seek innovative solutions to remain competitive.

Growing Interest in Remote Maintenance

The immersive technology-in-manufacturing market is witnessing a growing interest in remote maintenance solutions. As manufacturers seek to minimize downtime and enhance operational efficiency, immersive technologies such as AR are being employed to facilitate remote assistance. Technicians can utilize AR glasses to receive real-time guidance from experts located elsewhere, allowing for quicker problem resolution. This trend is particularly relevant in industries where equipment failure can lead to substantial financial losses. Recent statistics indicate that companies adopting remote maintenance solutions have reported a 20% reduction in maintenance costs. The potential for immersive technology to streamline maintenance processes and reduce operational disruptions positions it as a critical driver in the immersive technology-in-manufacturing market.

Customization and Personalization of Solutions

The immersive technology-in-manufacturing market is increasingly characterized by a demand for customization and personalization of solutions. As manufacturers seek to differentiate themselves in a competitive landscape, the ability to tailor immersive experiences to specific operational needs becomes crucial. This trend is evident in the development of bespoke VR training programs and AR applications designed to meet unique manufacturing challenges. Data indicates that companies offering customized immersive solutions have experienced a 15% increase in client satisfaction and retention rates. The emphasis on personalized experiences not only enhances user engagement but also drives the adoption of immersive technologies in manufacturing. Consequently, the focus on customization serves as a vital driver for the immersive technology-in-manufacturing market.

Integration of IoT with Immersive Technologies

The convergence of the Internet of Things (IoT) with immersive technologies is emerging as a transformative driver in the immersive technology-in-manufacturing market. By integrating IoT devices with VR and AR applications, manufacturers can gain real-time insights into their operations. This integration allows for enhanced data visualization, enabling operators to monitor equipment performance and make informed decisions swiftly. As IoT adoption in manufacturing is projected to reach 75% by 2026, the synergy between IoT and immersive technologies is likely to create new opportunities for innovation. This trend suggests that the immersive technology-in-manufacturing market will benefit from increased investments in IoT-enabled immersive solutions, further driving growth and efficiency.

Leave a Comment