Rising Demand for Mineral Resources

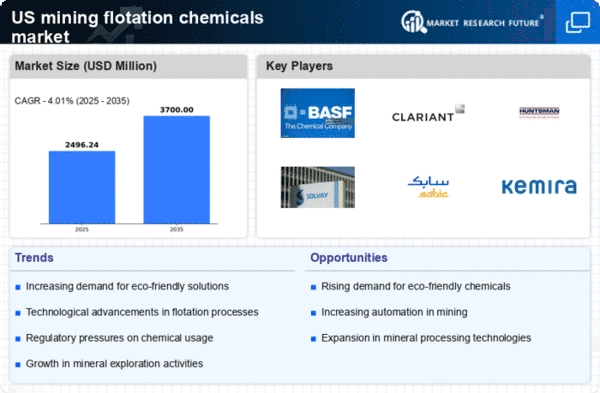

The mining flotation-chemicals market is experiencing a surge in demand driven by the increasing need for mineral resources in various industries. As the US economy continues to expand, sectors such as construction, electronics, and automotive are requiring more metals and minerals. This heightened demand is likely to propel mining operations, thereby increasing the consumption of flotation chemicals. In 2025, the market for flotation chemicals is projected to reach approximately $3 billion, reflecting a compound annual growth rate (CAGR) of around 4.01%. This growth indicates a robust market environment, where mining companies are investing in advanced flotation technologies to enhance recovery rates and optimize resource extraction. Consequently, the rising demand for mineral resources is a pivotal driver for the mining flotation-chemicals market.

Growing Focus on Operational Efficiency

The mining flotation-chemicals market is increasingly driven by a growing focus on operational efficiency among mining companies. As competition intensifies, companies are seeking ways to reduce costs and improve productivity. This has led to a heightened interest in optimizing flotation processes, which are critical for mineral recovery. By utilizing advanced flotation chemicals that enhance separation efficiency, mining operations can achieve higher yields with lower input costs. In 2025, it is estimated that operational efficiency initiatives will contribute to a 15% reduction in overall processing costs for mining companies. This emphasis on efficiency not only boosts profitability but also positions operational excellence as a vital driver for the mining flotation-chemicals market.

Increased Investment in Mining Exploration

The mining flotation-chemicals market is benefiting from increased investment in mining exploration activities across the US. As mineral reserves become more challenging to access, mining companies are allocating substantial resources towards exploration to identify new deposits. This trend is expected to result in a higher demand for flotation chemicals, as new mining projects require effective separation processes to extract valuable minerals. In 2025, exploration expenditures in the US mining sector are projected to exceed $1 billion, indicating a robust commitment to discovering new resources. This influx of investment is likely to stimulate growth in the mining flotation-chemicals market, as companies seek to enhance their operational capabilities through advanced flotation technologies.

Technological Innovations in Flotation Processes

Technological innovations are reshaping the mining flotation-chemicals market, as advancements in flotation processes lead to improved efficiency and recovery rates. The integration of automation and artificial intelligence in flotation systems is enabling mining companies to optimize their operations. For instance, the implementation of real-time monitoring systems allows for precise adjustments in chemical dosing, enhancing the overall performance of flotation processes. In 2025, it is anticipated that the adoption of such technologies will increase by approximately 20%, reflecting a growing trend towards automation in the mining sector. This technological evolution is likely to drive the demand for specialized flotation chemicals, positioning innovation as a key driver in the mining flotation-chemicals market.

Regulatory Compliance and Environmental Standards

The mining flotation-chemicals market is significantly influenced by stringent regulatory compliance and environmental standards imposed by US authorities. As environmental concerns gain prominence, mining companies are compelled to adopt sustainable practices, including the use of eco-friendly flotation chemicals. Regulations aimed at minimizing environmental impact are driving innovation in the development of biodegradable and less toxic flotation reagents. In 2025, it is estimated that around 30% of flotation chemicals used in the US will be derived from sustainable sources, reflecting a shift towards greener alternatives. This trend not only aligns with regulatory requirements but also enhances the reputation of mining companies, making regulatory compliance a crucial driver for the mining flotation-chemicals market.