Increased Demand for Automation

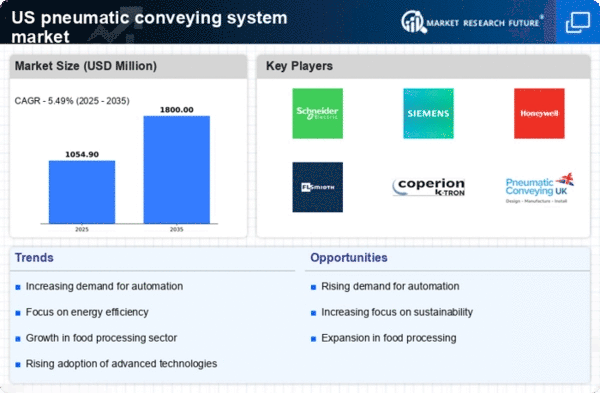

The pneumatic conveying-system market is experiencing a notable surge in demand for automation across various industries. As manufacturers strive to enhance operational efficiency, the integration of automated systems is becoming increasingly prevalent. This trend is particularly evident in sectors such as food processing, pharmaceuticals, and chemicals, where precision and speed are paramount. According to recent data, the automation market in the manufacturing sector is projected to grow at a CAGR of approximately 10% through 2026. This growth is likely to drive the adoption of pneumatic conveying systems, which offer seamless material handling solutions, thereby bolstering the overall market.

Advancements in Material Science

Innovations in material science are playing a pivotal role in shaping the pneumatic conveying-system market. The development of new materials that are lighter, stronger, and more resistant to wear and tear is enhancing the performance of pneumatic conveying systems. These advancements allow for the efficient handling of a wider range of materials, including abrasive and corrosive substances. As industries seek to optimize their operations, the demand for high-performance pneumatic conveying systems is likely to increase. The market for advanced materials is expected to grow at a CAGR of around 6% over the next few years, further driving the adoption of innovative pneumatic conveying solutions.

Rising Focus on Workplace Safety

Workplace safety remains a critical concern for industries utilizing pneumatic conveying systems. The pneumatic conveying-system market is influenced by the increasing emphasis on creating safer work environments. Companies are investing in advanced systems that minimize dust emissions and reduce the risk of explosions associated with bulk material handling. Regulatory bodies are also tightening safety standards, compelling organizations to adopt safer technologies. The market for safety equipment and systems is expected to grow significantly, with estimates suggesting a rise of around 8% annually. This focus on safety is likely to propel the demand for pneumatic conveying systems that comply with stringent safety regulations.

Growth in E-commerce and Logistics

The pneumatic conveying-system market is benefiting from the rapid expansion of e-commerce and logistics sectors. As online shopping continues to gain traction, the need for efficient material handling systems has become paramount. Warehouses and distribution centers are increasingly adopting pneumatic conveying systems to streamline operations and enhance productivity. Recent statistics indicate that the e-commerce market in the US is projected to reach $1 trillion by 2025, which could lead to a corresponding increase in demand for pneumatic conveying solutions. This growth presents a significant opportunity for manufacturers to innovate and cater to the evolving needs of the logistics industry.

Expansion of the Food and Beverage Sector

The food and beverage sector is a significant driver of the pneumatic conveying-system market. With the increasing demand for processed and packaged foods, manufacturers are investing in efficient material handling systems to meet production needs. The sector is projected to grow at a CAGR of approximately 5% through 2027, which is likely to boost the demand for pneumatic conveying systems that ensure hygienic and efficient transport of materials. Additionally, the need for compliance with food safety regulations is prompting companies to adopt advanced pneumatic conveying solutions that minimize contamination risks, thereby enhancing the overall market landscape.