Growth in Consumer Electronics

The thermoplastic polyolefins market is witnessing significant growth due to the increasing demand for consumer electronics. As technology advances, manufacturers are incorporating thermoplastic polyolefins into various electronic devices, including smartphones, laptops, and home appliances. These materials offer excellent durability, flexibility, and aesthetic appeal, making them ideal for consumer electronics applications. In 2025, the consumer electronics sector is expected to represent around 25% of the thermoplastic polyolefins market. The trend towards compact and lightweight designs in electronics further fuels the adoption of thermoplastic polyolefins, as they provide the necessary properties for modern devices. This growth in the consumer electronics sector is likely to drive innovation and expansion within the thermoplastic polyolefins market.

Expansion of the Packaging Industry

The thermoplastic polyolefins market is benefiting from the rapid expansion of the packaging industry. With the increasing demand for flexible and durable packaging solutions, thermoplastic polyolefins are being utilized for their excellent barrier properties and versatility. In 2025, the packaging sector is projected to account for nearly 40% of the thermoplastic polyolefins market, driven by the rise of e-commerce and the need for efficient packaging solutions. The lightweight nature of thermoplastic polyolefins also contributes to reduced shipping costs and improved sustainability in packaging. As consumer preferences shift towards convenience and sustainability, the packaging industry's growth is likely to further bolster the thermoplastic polyolefins market.

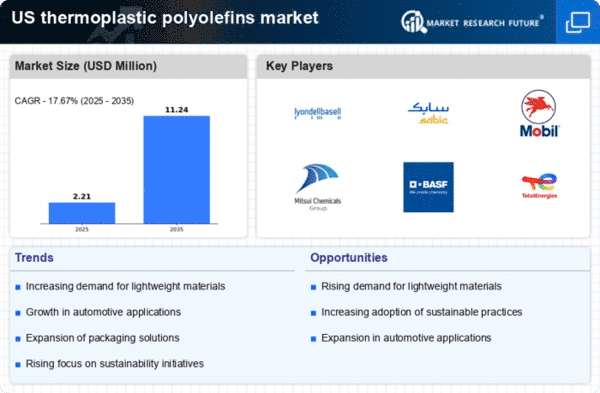

Rising Demand for Lightweight Materials

The thermoplastic polyolefins market is experiencing a notable increase in demand for lightweight materials across various industries. This trend is particularly pronounced in the automotive sector, where manufacturers are seeking to enhance fuel efficiency and reduce emissions. Lightweight materials, such as thermoplastic polyolefins, contribute to these goals by minimizing vehicle weight. In 2025, the automotive industry is projected to account for approximately 30% of the total thermoplastic polyolefins market, driven by stringent regulations on emissions and fuel economy. Additionally, the construction and packaging sectors are also adopting lightweight materials, further propelling the growth of the thermoplastic polyolefins market. As industries continue to prioritize sustainability and efficiency, the demand for lightweight thermoplastic polyolefins is likely to remain robust.

Increased Focus on Recycling and Circular Economy

The thermoplastic polyolefins market is increasingly influenced by the growing emphasis on recycling and the circular economy. As environmental concerns gain traction, industries are seeking sustainable solutions to reduce waste and promote resource efficiency. Thermoplastic polyolefins, known for their recyclability, are becoming a preferred choice for manufacturers aiming to align with circular economy principles. In 2025, it is anticipated that recycled thermoplastic polyolefins will constitute approximately 15% of the total market. This shift not only supports sustainability goals but also offers cost advantages for manufacturers. The integration of recycled materials into production processes is likely to enhance the competitiveness of the thermoplastic polyolefins market, as companies strive to meet consumer demand for eco-friendly products.

Technological Innovations in Manufacturing Processes

The thermoplastic polyolefins market is poised for growth due to ongoing technological innovations in manufacturing processes. Advances in production techniques, such as injection molding and extrusion, are enhancing the efficiency and quality of thermoplastic polyolefins. These innovations enable manufacturers to produce materials with improved properties, such as enhanced strength and flexibility, which are essential for various applications. In 2025, it is expected that technological advancements will contribute to a 20% increase in production capacity within the thermoplastic polyolefins market. As manufacturers adopt these new technologies, they are likely to achieve cost savings and improved product performance, further driving the market's expansion.