Growing Focus on Sustainability

The Vacuum Casting Machine Market is witnessing a growing focus on sustainability and eco-friendly manufacturing practices. As industries become more aware of their environmental impact, there is an increasing demand for processes that minimize waste and energy consumption. Vacuum casting, with its ability to produce high-quality parts with minimal material waste, aligns well with these sustainability goals. Recent studies indicate that companies implementing sustainable practices can reduce production costs by up to 30%. This shift towards greener manufacturing is likely to attract investments in vacuum casting technologies, further propelling the market. Additionally, as regulatory pressures increase, businesses are compelled to adopt more sustainable practices, thereby enhancing the appeal of vacuum casting as a viable manufacturing solution.

Expansion of the Automotive Sector

The Vacuum Casting Machine Market is significantly influenced by the expansion of the automotive sector. As manufacturers seek to enhance vehicle performance and aesthetics, the demand for lightweight and durable components has increased. Vacuum casting offers a viable solution for producing intricate parts that meet stringent quality standards. Recent statistics indicate that the automotive industry is expected to witness a growth rate of around 10% annually, which directly correlates with the rising adoption of vacuum casting technologies. This method not only facilitates the production of complex shapes but also allows for the use of various materials, including metals and plastics. Consequently, the growth of the automotive sector is likely to bolster the demand for vacuum casting machines, thereby enhancing the overall market landscape.

Rising Demand for Prototyping Solutions

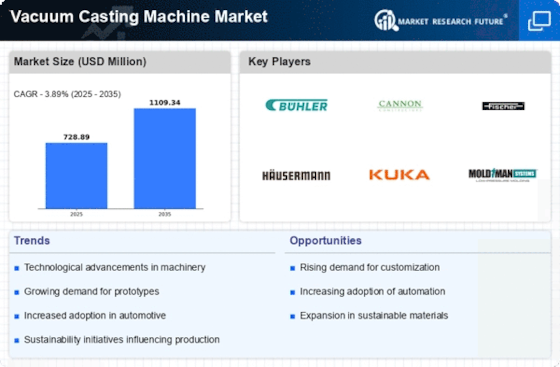

The Vacuum Casting Machine Market is experiencing a notable surge in demand for rapid prototyping solutions. Industries such as automotive, aerospace, and consumer electronics are increasingly adopting vacuum casting techniques to create high-quality prototypes. This method allows for the efficient production of intricate designs and complex geometries, which are essential for testing and validation processes. According to recent data, the prototyping segment is projected to grow at a compound annual growth rate of approximately 15% over the next five years. This growth is driven by the need for faster product development cycles and the ability to produce low-volume parts with high precision. As companies strive to innovate and reduce time-to-market, the vacuum casting process becomes an invaluable asset, thereby propelling the Vacuum Casting Machine Market forward.

Technological Advancements in Manufacturing

Technological advancements are playing a pivotal role in shaping the Vacuum Casting Machine Market. Innovations such as automation, artificial intelligence, and improved materials are enhancing the efficiency and precision of vacuum casting processes. These advancements enable manufacturers to produce high-quality components with reduced lead times and lower costs. For instance, the integration of AI-driven analytics allows for real-time monitoring and optimization of production processes. Market data suggests that the adoption of advanced technologies in manufacturing is expected to increase by 20% over the next few years. This trend not only improves operational efficiency but also elevates the quality of end products, making vacuum casting an attractive option for various industries. As a result, the ongoing technological evolution is likely to drive growth within the Vacuum Casting Machine Market.

Increased Adoption in Aerospace Applications

The Vacuum Casting Machine Market is experiencing increased adoption in aerospace applications, driven by the need for lightweight and high-strength components. The aerospace sector demands precision-engineered parts that can withstand extreme conditions, making vacuum casting an ideal choice. Recent market analysis reveals that the aerospace industry is projected to grow at a rate of 8% annually, which is likely to boost the demand for vacuum casting technologies. This method allows for the production of complex geometries and intricate designs that are essential for aircraft components. Furthermore, the ability to use advanced materials in vacuum casting enhances the performance and safety of aerospace products. As the aerospace industry continues to expand, the reliance on vacuum casting machines is expected to grow, thereby positively impacting the market.