Labor Shortages and Skills Gap

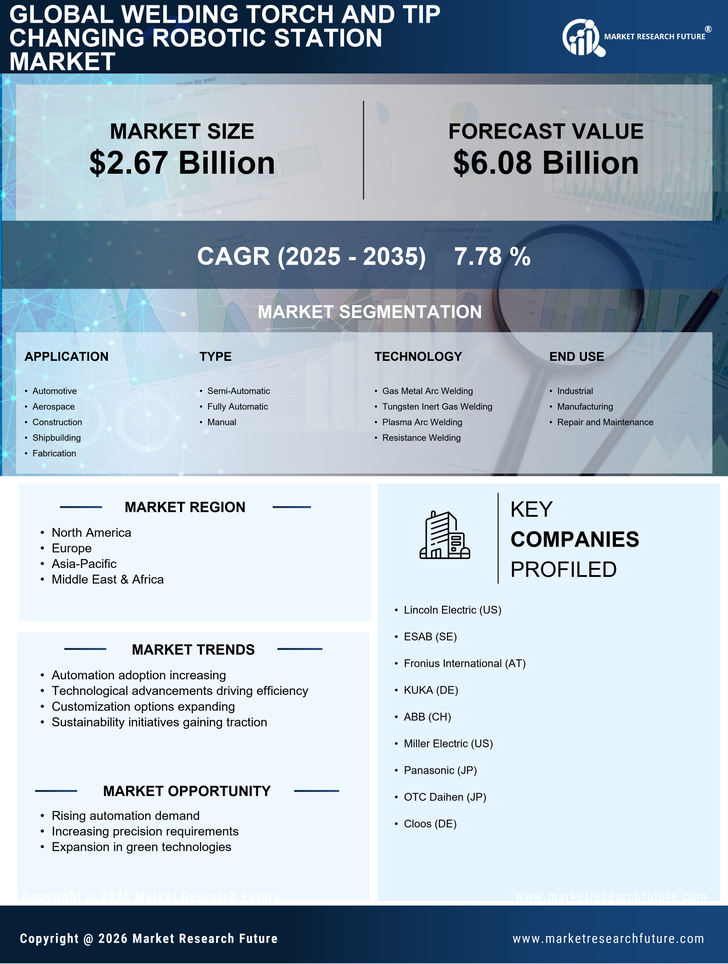

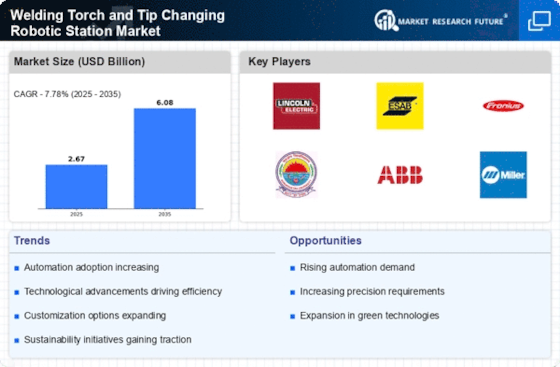

The Welding Torch and Tip Changing Robotic Station Market is significantly influenced by the ongoing labor shortages and skills gap in manufacturing sectors. As experienced welders retire, the demand for skilled labor outpaces supply, prompting manufacturers to seek automation solutions. Robotic stations that can efficiently change welding tips and perform welding tasks are increasingly viewed as viable alternatives to human labor. This shift not only addresses the labor shortage but also enhances productivity and reduces operational costs. Data suggests that companies investing in automation can achieve up to a 30% increase in efficiency, making the Welding Torch and Tip Changing Robotic Station Market an attractive option for manufacturers aiming to maintain competitiveness in a challenging labor market.

Rising Focus on Quality Control

Quality control remains a pivotal driver in the Welding Torch and Tip Changing Robotic Station Market. As industries face increasing scrutiny regarding product quality, the need for reliable welding processes becomes paramount. Robotic stations equipped with advanced monitoring systems can ensure that each weld meets predefined quality standards, thereby reducing the risk of defects. This focus on quality is particularly pronounced in sectors such as construction and heavy machinery, where the consequences of poor welding can be severe. The market data indicates that investments in quality control technologies are expected to rise, further propelling the demand for robotic welding solutions. Consequently, the Welding Torch and Tip Changing Robotic Station Market stands to benefit from this trend as manufacturers prioritize quality assurance in their production lines.

Increased Demand for Precision Welding

The Welding Torch and Tip Changing Robotic Station Market experiences heightened demand for precision welding solutions. Industries such as automotive and aerospace increasingly require high-quality welds to meet stringent safety and performance standards. This trend is driven by the need for enhanced product durability and reliability. As manufacturers strive to improve their production processes, the adoption of robotic stations that ensure consistent and precise welding becomes essential. According to recent data, the market for precision welding technologies is projected to grow significantly, indicating a robust opportunity for the Welding Torch and Tip Changing Robotic Station Market. The integration of advanced sensors and control systems in these robotic stations further enhances their capability to deliver precise welds, thereby attracting more industries to invest in automation.

Technological Advancements in Robotics

Technological advancements play a crucial role in shaping the Welding Torch and Tip Changing Robotic Station Market. Innovations in robotics, such as artificial intelligence and machine learning, are enhancing the capabilities of welding robots. These advancements allow for more sophisticated programming and adaptability to various welding tasks. As a result, manufacturers are increasingly inclined to invest in robotic stations that can seamlessly integrate with existing production lines. The market is witnessing a surge in the development of user-friendly interfaces and improved software solutions, which facilitate easier operation and maintenance of robotic systems. This trend suggests that the Welding Torch and Tip Changing Robotic Station Market is poised for growth as companies seek to leverage cutting-edge technologies to optimize their welding processes.

Environmental Regulations and Sustainability Initiatives

The Welding Torch and Tip Changing Robotic Station Market is also influenced by stringent environmental regulations and a growing emphasis on sustainability. Manufacturers are under pressure to reduce waste and emissions associated with welding processes. Robotic stations that optimize material usage and minimize energy consumption are increasingly favored. This shift towards sustainable practices not only helps companies comply with regulations but also enhances their brand image. Market data indicates that businesses adopting eco-friendly technologies can improve their market competitiveness. As sustainability becomes a core focus for many industries, the Welding Torch and Tip Changing Robotic Station Market is likely to see increased demand for solutions that align with these environmental goals.