Cost-Effectiveness of Recycled Filament

The 3d printer filament recycler Market is witnessing a shift towards the cost-effectiveness of recycled filament. As the price of raw materials fluctuates, manufacturers are increasingly turning to recycled options as a viable alternative. The production of recycled filament often incurs lower costs compared to virgin materials, particularly as recycling technologies improve and scale. Recent analyses suggest that companies utilizing recycled filament can reduce their material costs by up to 20%, enhancing their overall profitability. This economic advantage is likely to attract more businesses to the 3D Printer Filament Recycler Market, as they seek to optimize their supply chains and reduce expenses. Consequently, the growing recognition of the cost benefits associated with recycled filament is expected to drive market growth and innovation.

Rising Awareness of Plastic Waste Issues

The 3D Printer Filament Recycler Market is increasingly influenced by rising awareness of plastic waste issues. As consumers and businesses become more cognizant of the environmental impact of plastic pollution, there is a growing demand for solutions that mitigate this problem. The recycling of 3D printer filament presents a practical approach to addressing plastic waste, as it allows for the repurposing of materials that would otherwise contribute to landfills. Recent surveys indicate that a significant percentage of consumers are willing to pay a premium for products made from recycled materials, suggesting a shift in purchasing behavior. This heightened awareness is likely to drive growth within the 3D Printer Filament Recycler Market, as companies respond to consumer preferences by offering sustainable alternatives.

Increased Demand for Sustainable Practices

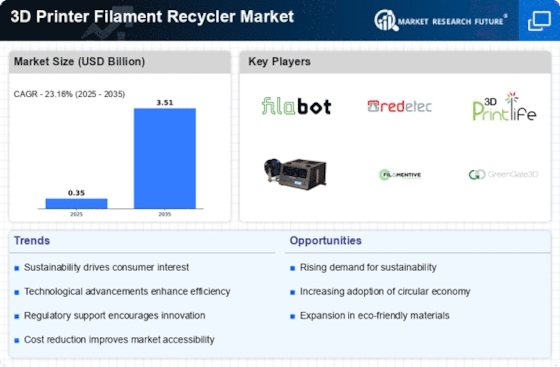

The 3D Printer Filament Recycler Market is experiencing a notable surge in demand for sustainable practices. As environmental concerns gain traction, manufacturers and consumers alike are increasingly prioritizing eco-friendly solutions. The recycling of 3D printer filament not only reduces waste but also conserves resources, aligning with global sustainability goals. According to recent data, the market for recycled materials is projected to grow significantly, with a compound annual growth rate (CAGR) of over 10% anticipated in the coming years. This trend indicates a shift towards circular economy principles, where materials are reused and repurposed, thereby enhancing the appeal of the 3D Printer Filament Recycler Market. Companies that invest in recycling technologies are likely to gain a competitive edge, as they cater to the growing consumer preference for sustainable products.

Regulatory Support for Recycling Initiatives

The 3D Printer Filament Recycler Market is benefiting from increasing regulatory support aimed at promoting recycling initiatives. Governments worldwide are implementing policies and regulations that encourage the use of recycled materials and the development of recycling infrastructure. This regulatory landscape is fostering an environment conducive to growth, as companies are incentivized to adopt sustainable practices. For instance, some regions have introduced tax breaks and grants for businesses that invest in recycling technologies. This support not only enhances the economic viability of recycling operations but also aligns with broader environmental objectives. As regulations continue to evolve, the 3D Printer Filament Recycler Market is likely to see a rise in participation from both established players and new entrants, further driving market expansion.

Technological Innovations in Recycling Processes

Technological advancements play a crucial role in shaping the 3D Printer Filament Recycler Market. Innovations in recycling processes, such as improved filament extrusion techniques and advanced sorting technologies, are enhancing the efficiency and effectiveness of recycling operations. These developments not only streamline the recycling process but also improve the quality of the recycled filament, making it a viable alternative to virgin materials. Recent studies indicate that the adoption of cutting-edge technologies could potentially increase recycling rates by up to 30%, thereby expanding the market. As manufacturers seek to optimize their production processes and reduce costs, the integration of innovative recycling technologies is likely to become a focal point within the 3D Printer Filament Recycler Market, driving growth and attracting investment.