Research Methodology on Aluminum Honeycomb Market

Introduction

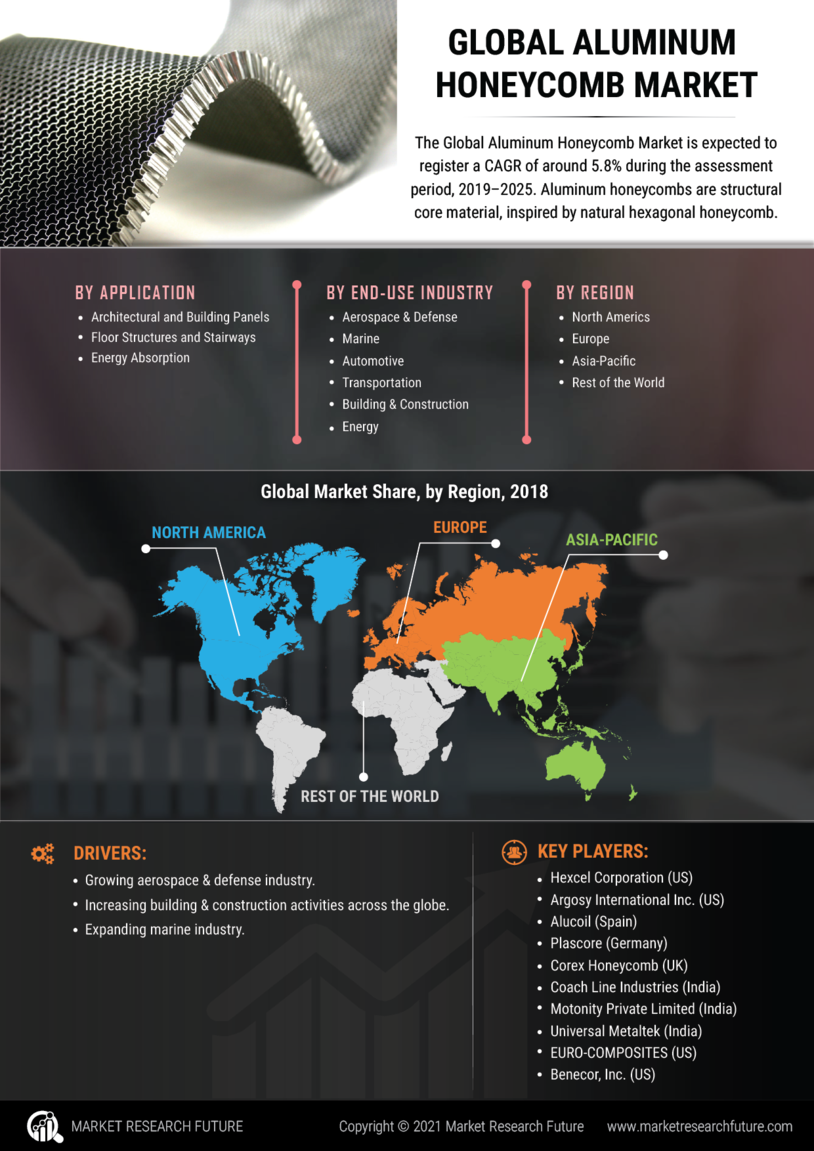

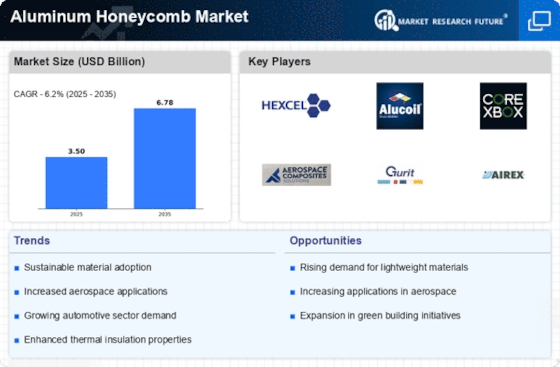

Aluminum honeycomb is a special type of composite material made of honeycomb-shaped cells filled with aluminum sheets in different shapes and used widely in both civil and military engineering applications. The aluminum honeycomb market has been experiencing steady growth in the past few years and is estimated to grow at an impressive CAGR during the forecast period of 2023-2030. The key drivers of aluminum honeycomb market growth include the increasing demand from the automobile industry and its applications in industries such as aerospace & defence, marine, construction, and wind energy. The growing popularity of lightweight materials in automobiles is also expected to drive the aluminum honeycomb market growth in the near future.

Research Methodology

This research report on the Global Aluminum Honeycomb Market is a comprehensive analysis of the market’s current and future trends and opportunities. It is based on primary and secondary research, which includes interviews with industry stakeholders, surveys, and market data such as annual reports, historical trends, etc. Secondary research sources include government publications, industry & trade associations, news sources, and databases such as Hoover’s, D&B, Bloomberg, Factiva, and S&P Capital IQ.

Design and data collection

In designing the research approach for this project, primary research and secondary research techniques have been combined to provide a more comprehensive market analysis. Primary research data collection has been conducted primarily through interviews with industry experts and key market stakeholders, such as manufacturers, suppliers, distributors, and end-users of aluminum honeycomb and raw material suppliers. Interviews were conducted using open-ended and closed-ended questions. Secondary data sources have also been used to supplement primary research.

Primary Data Collection

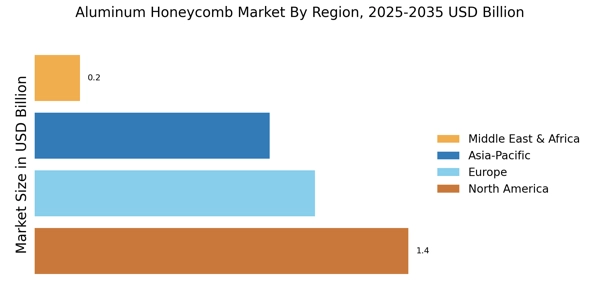

Face-to-face interviews have been conducted with industry experts from various locations, such as North America, Latin America, Europe, Asia-Pacific, and the Middle East. These stakeholders include manufacturers, suppliers, customers and industry professionals such as researchers, consultants, and advisors. The primary data collection sources provide qualitative, quantitative and descriptive information about market trends and opportunities. The interviews were conducted over the telephone and online and covered topics about the global aluminum honeycomb market.

Secondary Data Collection

Secondary data sources have been used to supplement primary research. These sources included trade publications, industry publications, market reports, press releases, government publications, and periodical journal articles related to the aluminum honeycomb market. Additionally, online databases such as Factiva, Emerald, Hoover's, company websites, and various public domain documents have also been used to collect quantitative and qualitative information about the industry.

Data Analysis

The research team employed both qualitative and quantitative techniques in the process of analysing the data collected from primary and secondary sources. The quantitative analysis was used to forecast the market size and demand for silicon in terms of market share. The qualitative analysis, on the other hand, was performed by analyzing the trends that are impacting the market.

The research team also employed a bottom-up/top-down approach, factor analysis, time-series analysis and demand and supply side data triangulation to analyse the data collected and make better sense of the market in order to come up with an accurate and reliable market estimate. The data gathered from primary and secondary sources were analysed using SPSS and MS Excel.

Conclusion

The comprehensive research methodology adopted for this research report on the global aluminum honeycomb market has enabled the research team to generate reliable and accurate market estimates and forecasts. With the help of primary and secondary research, a thorough market analysis has been conducted, which includes both qualitative and quantitative analysis. The market estimates and forecasts have been generated by analysing the data collected and using various analytical techniques, such as bottom-up/top-down approach, factor analysis, time-series analysis and demand and supply side data triangulation. These techniques have enabled the research team to arrive at sound conclusions and generate reliable market estimates. The research report also provides a detailed SWOT analysis of the market and the key players operating in the market. The report provides an in-depth analysis of the market and a comprehensive understanding of the competitive landscape.