Sustainability Initiatives

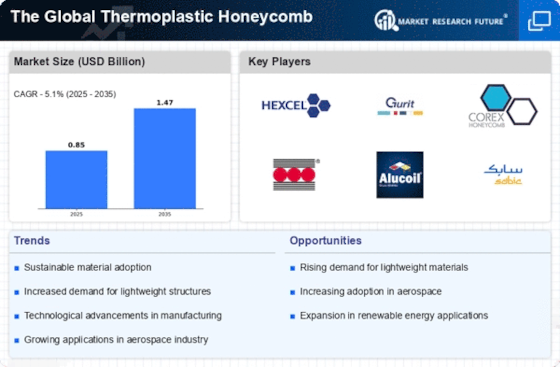

The increasing emphasis on sustainability initiatives is a pivotal driver for The Global Thermoplastic Honeycomb Industry. As industries strive to reduce their carbon footprint, thermoplastic honeycomb materials, known for their recyclability and lightweight properties, are gaining traction. The market is projected to witness a compound annual growth rate (CAGR) of approximately 5% over the next few years, driven by the demand for eco-friendly materials. Manufacturers are increasingly adopting thermoplastic honeycomb structures in various applications, including automotive and construction, to enhance energy efficiency and reduce waste. This shift towards sustainable practices not only aligns with regulatory requirements but also meets consumer preferences for environmentally responsible products. Consequently, The Global Thermoplastic Honeycomb Industry is likely to expand as companies prioritize sustainability in their material choices.

Technological Advancements

Technological advancements play a crucial role in shaping The Global Thermoplastic Honeycomb Industry. Innovations in manufacturing processes, such as automated production techniques and advanced composite materials, are enhancing the performance and application range of thermoplastic honeycomb structures. For instance, the introduction of 3D printing technology has enabled the creation of complex geometries that were previously unattainable, thereby broadening the scope of applications in aerospace, automotive, and construction sectors. The market is expected to grow as these technologies improve the efficiency and cost-effectiveness of thermoplastic honeycomb products. Furthermore, ongoing research and development efforts are likely to yield new materials with superior properties, further driving the adoption of thermoplastic honeycomb solutions. As a result, The Global Thermoplastic Honeycomb Industry is positioned for significant growth in the coming years.

Growing Demand in Aerospace

The growing demand in the aerospace sector is a significant driver for The Global Thermoplastic Honeycomb Industry. As airlines and manufacturers seek to enhance fuel efficiency and reduce operational costs, lightweight materials such as thermoplastic honeycomb are increasingly favored. The aerospace industry is projected to expand at a CAGR of around 4% in the coming years, with thermoplastic honeycomb structures being utilized in aircraft interiors, fuselage components, and cargo systems. These materials not only contribute to weight reduction but also offer excellent mechanical properties and durability. The shift towards more efficient aircraft designs is likely to propel the demand for thermoplastic honeycomb solutions, thereby positively impacting The Global Thermoplastic Honeycomb Industry. This trend underscores the importance of innovation and material selection in meeting the evolving needs of the aerospace sector.

Expansion in Construction Sector

The expansion in the construction sector is emerging as a key driver for The Global Thermoplastic Honeycomb Industry. As urbanization accelerates and infrastructure projects proliferate, the demand for lightweight and durable building materials is on the rise. Thermoplastic honeycomb structures are increasingly being utilized in applications such as wall panels, flooring, and roofing systems due to their excellent strength-to-weight ratio and insulation properties. The construction industry is projected to grow at a CAGR of around 5% in the next few years, which is likely to enhance the adoption of thermoplastic honeycomb materials. This growth is further supported by the need for energy-efficient building solutions that comply with modern sustainability standards. Consequently, The Global Thermoplastic Honeycomb Industry is expected to benefit from the ongoing developments in the construction sector.

Increasing Applications in Automotive

The increasing applications of thermoplastic honeycomb materials in the automotive industry serve as a vital driver for The Global Thermoplastic Honeycomb Industry. With the automotive sector focusing on lightweighting to improve fuel efficiency and reduce emissions, thermoplastic honeycomb structures are being integrated into various components, including body panels and interior parts. The market is anticipated to grow as manufacturers adopt these materials to comply with stringent environmental regulations and consumer demands for more sustainable vehicles. The automotive industry is expected to witness a growth rate of approximately 3% in the coming years, further bolstering the demand for thermoplastic honeycomb solutions. This trend highlights the critical role of material innovation in enhancing vehicle performance and sustainability, thereby influencing the trajectory of The Global Thermoplastic Honeycomb Industry.