Rising Infrastructure Investments

The APAC aluminum extrusion market is surging due to increased infrastructure investments.. Governments across the region are allocating substantial budgets for transportation, energy, and urban development projects. For instance, the Asian Development Bank has projected that infrastructure investments in APAC could reach $26 trillion by 2030. This influx of capital is likely to drive demand for aluminum extrusions, which are favored for their lightweight and durable properties. The construction of roads, bridges, and railways often utilizes aluminum extrusions for structural components, thereby enhancing the market's growth potential. As urbanization continues to rise, the need for efficient and sustainable building materials becomes paramount, further propelling the aluminum extrusion market in APAC.

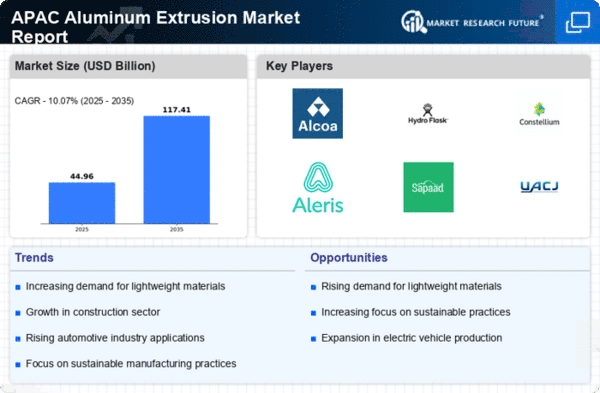

Shift Towards Lightweight Materials

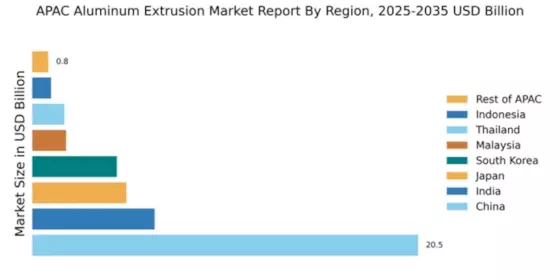

The APAC aluminum extrusion market is benefiting from a shift towards lightweight materials.. As manufacturers seek to enhance fuel efficiency and reduce emissions, aluminum's lightweight nature makes it an attractive option. In the automotive sector, for example, the use of aluminum extrusions can lead to weight reductions of up to 30%, which translates to improved fuel economy. This trend is particularly relevant in countries like Japan and South Korea, where stringent regulations on emissions are in place. Additionally, the aerospace industry is increasingly adopting aluminum extrusions for similar reasons. The growing emphasis on lightweight materials is expected to bolster the aluminum extrusion market, as industries strive to meet both regulatory requirements and consumer expectations.

Environmental Regulations and Standards

The APAC aluminum extrusion market is influenced by stringent environmental regulations.. Governments are implementing policies aimed at reducing carbon footprints and promoting sustainable practices. For example, the introduction of recycling mandates and emissions targets is compelling manufacturers to adopt more eco-friendly production methods. This regulatory landscape is likely to drive demand for recycled aluminum extrusions, which are perceived as more sustainable. In countries like China, where environmental concerns are paramount, the push for greener alternatives is reshaping the market dynamics. As industries adapt to these regulations, the aluminum extrusion market is expected to witness a shift towards more sustainable practices, thereby enhancing its appeal to environmentally conscious consumers.

Growing Demand from the Electronics Sector

The APAC aluminum extrusion market is experiencing heightened demand from the electronics sector., driven by the increasing need for lightweight and efficient thermal management solutions. As electronic devices become more compact and powerful, the requirement for effective heat dissipation has become critical. Aluminum extrusions are widely utilized in heat sinks and enclosures due to their excellent thermal conductivity and lightweight properties. The rapid growth of the consumer electronics market, particularly in countries like China and India, is likely to further propel this demand. Additionally, the trend towards miniaturization in electronics is expected to create new opportunities for aluminum extrusions, as manufacturers seek innovative solutions to meet evolving consumer needs. This growing intersection between electronics and aluminum extrusion is poised to significantly impact the market landscape.

Technological Innovations in Manufacturing

Technological advancements in manufacturing processes are significantly impacting the aluminum extrusion market in APAC. Innovations such as 3D printing and advanced extrusion techniques are enhancing production efficiency and product quality. For instance, the introduction of automated extrusion lines has been shown to increase output by as much as 20%, while reducing waste. Furthermore, the development of new alloys and surface treatments is expanding the application range of aluminum extrusions, making them suitable for more demanding environments. This evolution in manufacturing technology not only improves the competitiveness of aluminum extrusions but also aligns with the growing demand for high-performance materials in sectors such as construction and automotive. As these technologies continue to evolve, they are likely to play a crucial role in shaping the future of the aluminum extrusion market in APAC.