Increase in Vehicle Production

The Automotive Connecting Rod Bolt Market is poised for growth due to the increase in vehicle production across various segments. As economies recover and consumer confidence rises, automotive manufacturers are ramping up production to meet the growing demand for personal and commercial vehicles. This surge in production directly correlates with the need for connecting rod bolts, which are essential for engine assembly. Recent statistics indicate that vehicle production is expected to reach over 100 million units annually by 2026, creating a substantial market for automotive components. Consequently, the Automotive Connecting Rod Bolt Market stands to gain from this upward trend, as manufacturers seek to ensure quality and reliability in their engine components.

Rising Demand for Fuel Efficiency

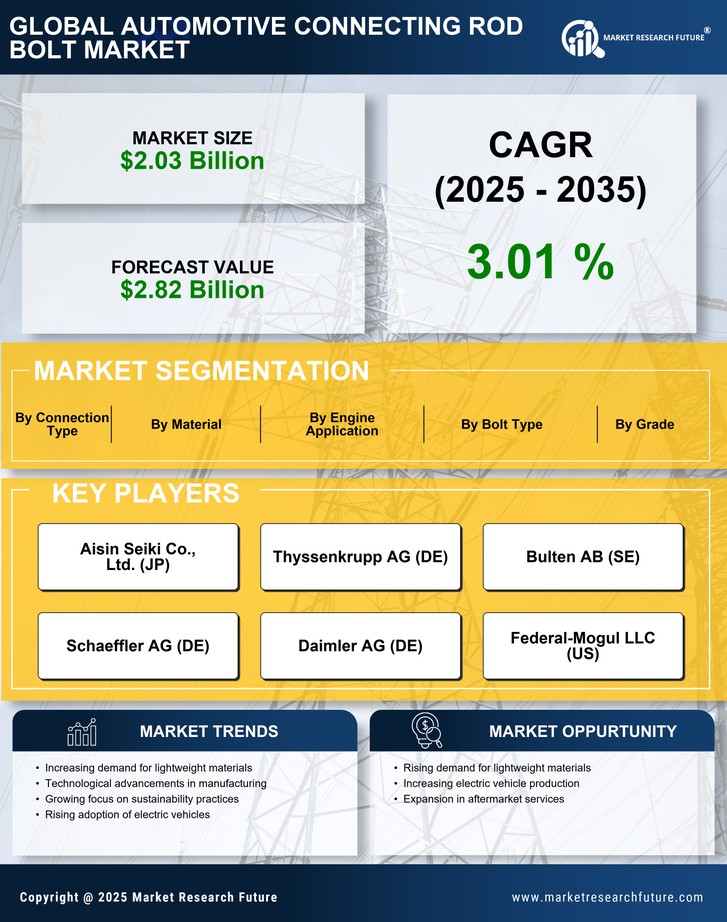

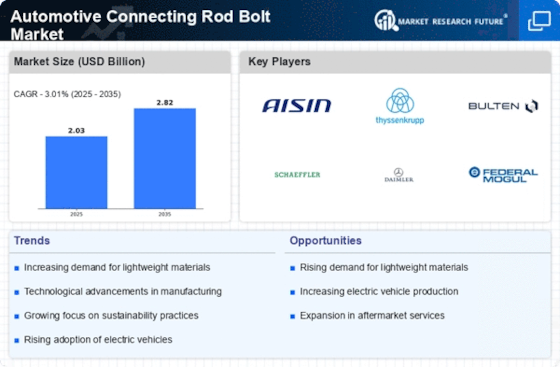

The Automotive Connecting Rod Bolt Market is experiencing a notable increase in demand for fuel-efficient vehicles. As consumers become more environmentally conscious, manufacturers are compelled to enhance the fuel efficiency of their offerings. This trend is driving the need for advanced materials and components, including connecting rod bolts, which play a crucial role in engine performance. According to recent data, the automotive sector is projected to witness a compound annual growth rate of approximately 4.5% in the coming years, further emphasizing the importance of optimizing engine components. Consequently, the Automotive Connecting Rod Bolt Market is likely to benefit from this shift towards fuel efficiency, as manufacturers seek to innovate and improve their products to meet consumer expectations.

Growth of Electric and Hybrid Vehicles

The Automotive Connecting Rod Bolt Market is witnessing a transformation due to the growth of electric and hybrid vehicles. As the automotive landscape shifts towards electrification, the design and manufacturing of engine components, including connecting rod bolts, are evolving. Electric and hybrid vehicles often require different specifications and materials to optimize performance and efficiency. This shift presents both challenges and opportunities for manufacturers in the Automotive Connecting Rod Bolt Market. The market for electric vehicles is projected to grow at a rate of 20% annually, indicating a substantial shift in consumer preferences. Consequently, manufacturers must adapt their product offerings to cater to this emerging segment, ensuring that connecting rod bolts meet the unique demands of electric and hybrid powertrains.

Technological Advancements in Engine Design

Technological advancements in engine design are significantly influencing the Automotive Connecting Rod Bolt Market. Innovations such as variable valve timing and turbocharging require more robust and reliable components, including connecting rod bolts. These advancements necessitate the use of high-strength materials that can withstand increased stress and temperature variations. As a result, manufacturers are investing in research and development to create connecting rod bolts that meet these new demands. The market for high-performance engine components is expected to grow, with estimates suggesting a potential increase of 6% annually. This growth indicates a promising future for the Automotive Connecting Rod Bolt Market as it adapts to the evolving landscape of engine technology.

Regulatory Standards for Emissions and Safety

The Automotive Connecting Rod Bolt Market is significantly impacted by stringent regulatory standards for emissions and safety. Governments worldwide are implementing more rigorous regulations to reduce vehicle emissions and enhance safety features. These regulations compel manufacturers to adopt advanced technologies and materials in their engine designs, including the use of high-quality connecting rod bolts. Compliance with these standards often requires the integration of innovative solutions that improve engine efficiency and durability. As a result, the Automotive Connecting Rod Bolt Market is likely to see increased demand for specialized components that meet these regulatory requirements, driving growth and innovation within the sector.