Enhanced Aesthetic Appeal

Aesthetic considerations play a pivotal role in the Automotive Magnesium Wheel Market, as consumers increasingly seek visually appealing designs that complement their vehicles. Magnesium wheels offer a unique combination of lightweight properties and sleek designs, which can enhance the overall look of a vehicle. This aesthetic appeal is particularly important in the luxury and performance vehicle segments, where consumers are willing to invest in premium materials that not only improve performance but also elevate the vehicle's visual impact. As manufacturers continue to innovate in design and finish options, the demand for magnesium wheels is expected to grow, potentially leading to a market expansion of approximately 8% in the coming years.

Weight Reduction Benefits

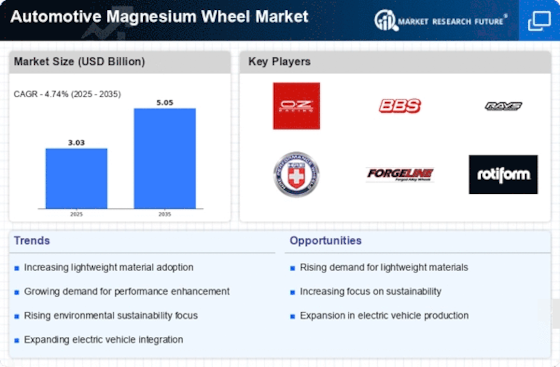

The Automotive Magnesium Wheel Market is experiencing a notable shift towards lightweight materials, primarily due to the increasing demand for fuel efficiency and performance enhancement in vehicles. Magnesium wheels are significantly lighter than traditional aluminum or steel options, which can lead to improved acceleration, braking, and handling. This weight reduction is particularly advantageous for electric vehicles, where every kilogram saved can enhance range and efficiency. As manufacturers strive to meet stringent emissions regulations, the adoption of magnesium wheels is likely to rise, potentially leading to a market growth rate of around 10% annually over the next few years. The emphasis on weight reduction is thus a critical driver in the Automotive Magnesium Wheel Market.

Cost-Effectiveness of Production

The Automotive Magnesium Wheel Market is also influenced by the cost-effectiveness of magnesium wheel production. Advances in manufacturing techniques, such as die casting and thixomolding, have made it more feasible to produce magnesium wheels at competitive prices. This reduction in production costs can make magnesium wheels an attractive option for manufacturers looking to balance performance and affordability. As the automotive industry continues to seek ways to optimize production processes and reduce costs, the adoption of magnesium wheels is likely to increase. This trend may lead to a market growth rate of approximately 9% as more manufacturers recognize the economic advantages of incorporating magnesium wheels into their offerings.

Rising Electric Vehicle Adoption

The Automotive Magnesium Wheel Market is poised for growth due to the rising adoption of electric vehicles (EVs). As the automotive landscape shifts towards electrification, manufacturers are increasingly incorporating lightweight materials to enhance the efficiency and performance of EVs. Magnesium wheels, with their superior strength-to-weight ratio, are particularly well-suited for electric vehicles, where reducing weight can significantly improve battery range and overall performance. The global push for sustainable transportation solutions is likely to drive the demand for magnesium wheels in the EV segment, with projections indicating a potential market growth of around 12% as more automakers integrate these wheels into their designs.

Regulatory Support for Lightweight Materials

The Automotive Magnesium Wheel Market is benefiting from increasing regulatory support for lightweight materials aimed at reducing vehicle emissions. Governments worldwide are implementing stricter fuel economy standards and emissions regulations, which encourage manufacturers to adopt lighter materials in vehicle production. Magnesium wheels, being lighter than traditional materials, align well with these regulatory trends. As automakers strive to comply with these regulations, the demand for magnesium wheels is expected to rise, potentially resulting in a market growth of around 11% in the next few years. This regulatory environment thus serves as a significant driver for the Automotive Magnesium Wheel Market.