Growing Focus on Sustainability

The Automotive Tire Mold Market is increasingly influenced by a growing focus on sustainability and eco-friendly practices. As consumers become more environmentally conscious, tire manufacturers are under pressure to produce sustainable products. This shift is prompting the development of molds that facilitate the production of tires made from renewable materials and those that minimize waste during the manufacturing process. In 2025, the demand for sustainable tire solutions is expected to rise, driving the Automotive Tire Mold Market to innovate in mold design and materials. Manufacturers are likely to invest in research and development to create molds that support the production of eco-friendly tires, aligning with global sustainability goals.

Regulatory Standards and Compliance

The Automotive Tire Mold Market is significantly influenced by evolving regulatory standards and compliance requirements. Governments worldwide are increasingly implementing stringent regulations regarding tire safety, performance, and environmental impact. These regulations necessitate the production of tires that adhere to specific criteria, thereby increasing the demand for advanced tire molds capable of producing compliant products. In 2025, it is anticipated that the Automotive Tire Mold Market will see a surge in demand for molds that facilitate the production of tires meeting these regulatory standards. This trend underscores the importance of innovation in mold design and manufacturing processes to ensure compliance while maintaining efficiency.

Expansion of Electric Vehicle Market

The Automotive Tire Mold Market is poised for growth due to the rapid expansion of the electric vehicle (EV) market. As EV adoption increases, there is a corresponding need for tires specifically designed to accommodate the unique requirements of electric vehicles, such as lower rolling resistance and enhanced grip. In 2025, the EV market is expected to account for a substantial share of new vehicle sales, which in turn drives the demand for specialized tire molds. Manufacturers are likely to invest in developing molds that cater to these innovative tire designs, thereby propelling the Automotive Tire Mold Market forward. This trend indicates a shift in focus towards molds that can produce tires optimized for electric mobility.

Rising Demand for High-Performance Tires

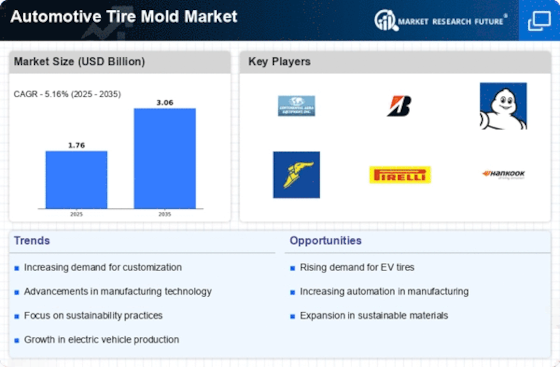

The Automotive Tire Mold Market is experiencing a notable increase in demand for high-performance tires, driven by consumer preferences for enhanced safety, durability, and fuel efficiency. As automotive manufacturers strive to meet these expectations, the need for advanced tire molds becomes critical. In 2025, the market for high-performance tires is projected to grow significantly, with estimates suggesting a compound annual growth rate of around 5.5%. This growth directly influences the Automotive Tire Mold Market, as manufacturers require specialized molds to produce tires that meet stringent performance standards. Consequently, the demand for innovative mold designs and materials is likely to rise, pushing the industry towards more sophisticated manufacturing techniques.

Technological Innovations in Manufacturing Processes

The Automotive Tire Mold Market is benefiting from ongoing technological innovations in manufacturing processes. Advancements such as 3D printing and computer-aided design (CAD) are revolutionizing mold production, allowing for greater precision and customization. These technologies enable manufacturers to create complex mold geometries that were previously unattainable, thus enhancing the overall quality of tire production. In 2025, the integration of these technologies is expected to streamline operations within the Automotive Tire Mold Market, reducing lead times and costs associated with mold production. As manufacturers adopt these innovations, the industry is likely to witness a transformation in how molds are designed and produced, leading to improved efficiency and product quality.

.png)