Top Industry Leaders in the Carbon Fiber Automotive Market

Introduction:

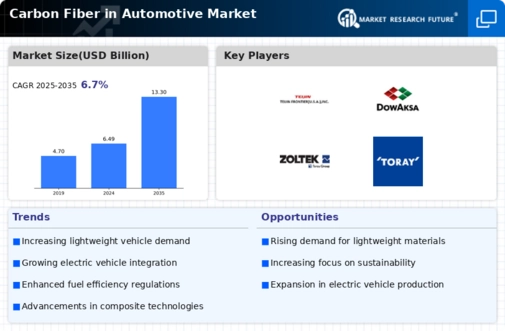

The automotive industry is experiencing a paradigm shift towards lightweight materials, and carbon fiber stands at the forefront of this revolution. Its exceptional strength-to-weight ratio, superior rigidity, and design flexibility make it the dream material for automakers aiming to achieve enhanced performance, fuel efficiency, and aesthetic appeal. This growth has ignited a fierce competition among established and emerging players vying for a larger slice of this lucrative pie.

List of Strategies Adopted:

- Product Diversification: Leading players like Toray Industries and SGL Carbon are expanding their portfolios beyond traditional panels and driveshafts to include complex structural components like chassis and battery enclosures. This caters to the growing demand for lightweighting across critical vehicle parts.

- Vertical Integration: Companies like Mitsubishi Chemical are investing in backward integration, acquiring raw material sources and controlling production processes to ensure stable supply and cost competitiveness.

- Technological Innovation: R&D in new manufacturing techniques like automated fiber placement and resin transfer molding is crucial for reducing production costs and increasing output. Companies like BMW and Ford are collaborating with research institutions to accelerate this innovation.

- Strategic Partnerships: Partnerships with automakers and tier-1 suppliers are critical for securing long-term contracts and gaining access to cutting-edge vehicle platforms. Collaboration between Toray and Ford for the Mustang Shelby GT500's carbon fiber wheels is a prime example.

- Focus on Sustainability: Sustainability is becoming a key differentiator, with companies like Teijin developing bio-based and recyclable carbon fiber solutions to cater to environmentally conscious consumers and stricter regulations.

Factors for Market Share:

- Production Capacity: Companies with large production capacities like SGL Carbon and Cytec Industries have a clear advantage in securing major contracts and meeting the growing demand.

- Cost Competitiveness: Reducing production costs remains a primary challenge. Companies like Hexcel are optimizing manufacturing processes and exploring alternative materials to make carbon fiber more accessible for mainstream vehicles.

- Technological Expertise: Possessing in-house expertise in material science, engineering, and automation is crucial for developing next-generation carbon fiber solutions and staying ahead of the curve.

- Brand Reputation: Established players like Toray Industries and Mitsubishi Chemical benefit from their longstanding reputation for quality and reliability, giving them an edge in securing contracts with premium car manufacturers.

- Geographical Presence: Having production facilities close to major automotive hubs enables faster delivery and reduces logistical costs, providing a competitive advantage for companies like Teijin in the Asian market.

List of Key Players in the Carbon Fiber in Automotive Market

-

Hexcel Corporation (US)

-

Mitsubishi Chemical Carbon Fiber and Composites Inc. (US)

-

SGL Carbon SE (Germany)

-

Cytec Solvay Group (US)

-

Teijin Limited (Japan)

-

DOWAKSA (US)

-

Formosa Plastic Corp. (Taiwan)

-

ZOLTEK (US)

-

Sigmatex Ltd

-

Toray Industries Inc. (Japan)

Recent Developments:

November 2023: A group of Japanese companies announce a consortium to develop and commercialize recycled carbon fiber for automotive applications.

December 2023: A start-up in California unveils a new bio-based carbon fiber made from algae, offering a more sustainable alternative to traditional production methods.

October 2023: The European Commission invests €200 million in research projects aimed at developing low-cost and high-volume carbon fiber production technologies.

September 2023: A new report predicts that the use of carbon fiber in electric vehicle battery packs will grow rapidly, driven by the need for lighter and more efficient batteries.