Rising Demand in Electrical Applications

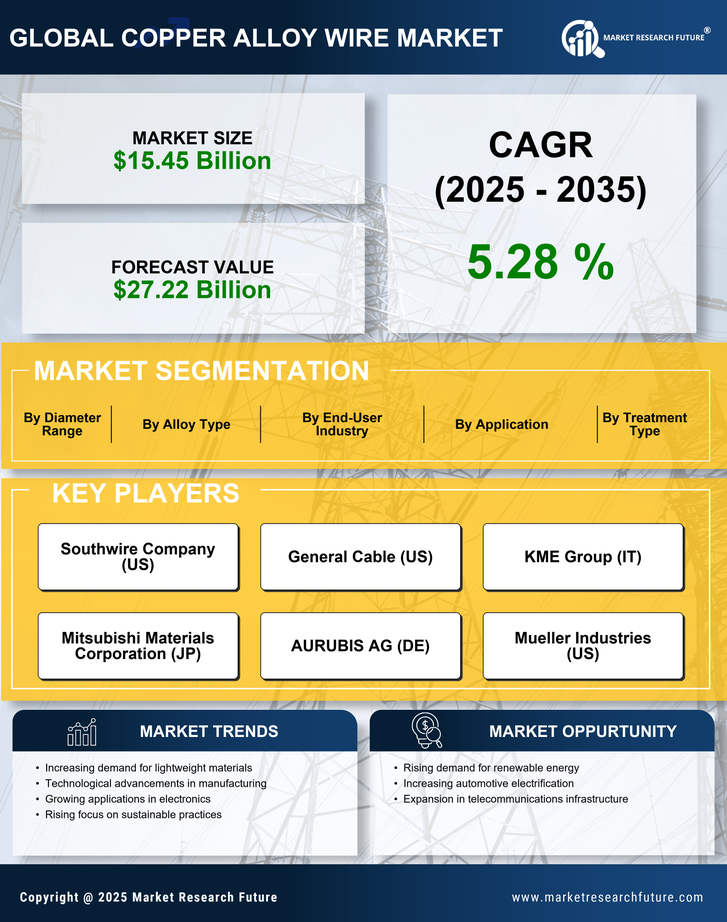

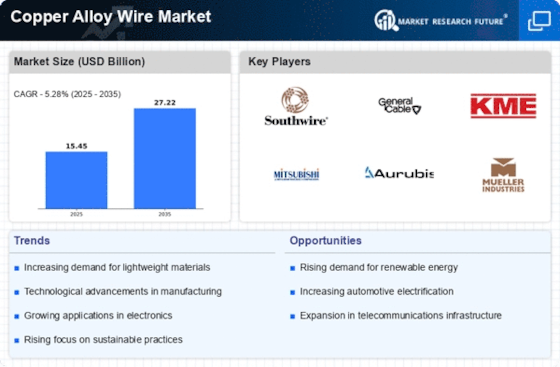

The Copper Alloy Wire Market is experiencing a notable increase in demand driven by the expanding electrical sector. Copper alloys are favored for their excellent conductivity and durability, making them ideal for electrical wiring and components. As industries such as renewable energy and electric vehicles grow, the need for high-quality copper alloy wires is expected to rise. Reports indicate that the electrical applications segment could account for a substantial share of the market, potentially exceeding 40% by 2026. This trend suggests that manufacturers in the Copper Alloy Wire Market must adapt to meet the evolving needs of the electrical sector.

Growth in Telecommunications Infrastructure

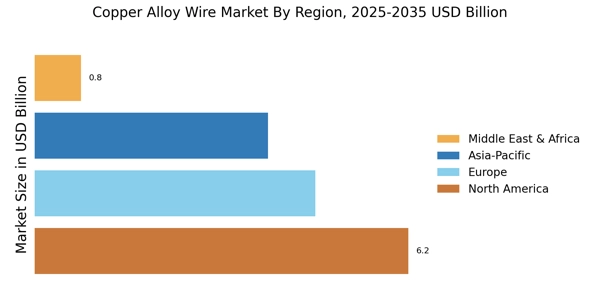

The Copper Alloy Wire Market is significantly influenced by the ongoing expansion of telecommunications infrastructure. As the demand for high-speed internet and advanced communication systems increases, the need for reliable wiring solutions becomes paramount. Copper alloys, known for their superior conductivity and resistance to corrosion, are essential in the manufacturing of cables and connectors used in telecommunications. Recent data indicates that investments in telecommunications infrastructure are projected to reach unprecedented levels, further driving the demand for copper alloy wires. This growth presents opportunities for companies within the Copper Alloy Wire Market to innovate and enhance their product offerings.

Increased Focus on Renewable Energy Sources

The Copper Alloy Wire Market is poised for growth due to the heightened focus on renewable energy sources. As countries strive to reduce carbon emissions and transition to sustainable energy, the demand for copper alloy wires in solar and wind energy applications is likely to surge. Copper alloys are integral in the manufacturing of components such as inverters and connectors, which are crucial for efficient energy transmission. Market analysis suggests that the renewable energy sector could contribute significantly to the overall growth of the Copper Alloy Wire Market, with projections indicating a compound annual growth rate of over 5% in the coming years.

Expanding Automotive Sector and Electric Vehicles

The Copper Alloy Wire Market is significantly impacted by the expansion of the automotive sector, particularly with the rise of electric vehicles (EVs). Copper alloys are essential in various automotive applications, including wiring harnesses and battery connections, due to their excellent conductivity and lightweight properties. As the automotive industry increasingly shifts towards electrification, the demand for copper alloy wires is expected to grow substantially. Recent estimates suggest that the automotive sector could account for a considerable portion of the Copper Alloy Wire Market, potentially reaching 30% by 2027. This trend underscores the importance of adapting to the evolving needs of the automotive market.

Technological Innovations in Manufacturing Processes

The Copper Alloy Wire Market is benefiting from technological innovations that enhance manufacturing processes. Advances in production techniques, such as improved casting and drawing methods, allow for the creation of high-performance copper alloy wires with superior properties. These innovations not only increase efficiency but also reduce production costs, making it more feasible for manufacturers to meet the rising demand. Furthermore, the integration of automation and smart technologies in manufacturing is expected to streamline operations within the Copper Alloy Wire Market. This trend indicates a shift towards more sustainable and cost-effective production practices, which could reshape the competitive landscape.