Focus on Safety and Risk Mitigation

Safety considerations are becoming increasingly paramount in the drone wind turbine blade inspection Market. The inherent risks associated with manual inspections, particularly at great heights, have prompted operators to seek safer alternatives. drones significantly reduce the need for personnel to work at dangerous elevations, thereby minimizing the risk of accidents. Moreover, regular inspections facilitated by drones can lead to early detection of potential failures, which is crucial for preventing catastrophic incidents. The emphasis on safety and risk mitigation aligns with broader industry trends towards operational excellence and sustainability. As safety standards continue to tighten, the adoption of drone technology for wind turbine blade inspections is likely to gain momentum, further driving the Drone Wind Turbine Blade Inspection Market.

Increased Demand for Renewable Energy

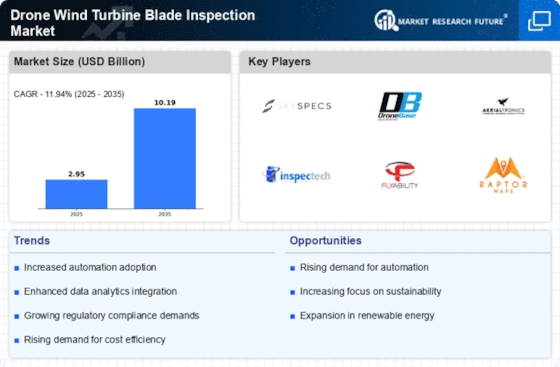

The rising demand for renewable energy sources is a primary driver for the Drone Wind Turbine Blade Inspection Market. As countries strive to meet their energy needs sustainably, wind energy has emerged as a crucial component. The International Energy Agency indicates that wind power capacity has been steadily increasing, with projections suggesting a doubling of capacity by 2030. This surge necessitates regular maintenance and inspection of wind turbine blades to ensure efficiency and safety. Drones, with their ability to conduct rapid and thorough inspections, are becoming indispensable in this context. The integration of drone technology not only enhances inspection accuracy but also reduces downtime, thereby supporting the overall growth of the Drone Wind Turbine Blade Inspection Market.

Cost Efficiency and Operational Savings

Cost efficiency is a significant driver influencing the Drone Wind Turbine Blade Inspection Market. Traditional inspection methods often involve extensive labor and equipment costs, which can be prohibitive for many operators. Drones offer a more economical alternative, enabling inspections to be conducted quickly and with fewer resources. According to industry estimates, drone inspections can reduce costs by up to 50% compared to conventional methods. This financial advantage is particularly appealing to operators managing multiple wind farms, as it allows for more frequent inspections without straining budgets. Consequently, the shift towards drone technology is likely to accelerate, further propelling the Drone Wind Turbine Blade Inspection Market.

Regulatory Frameworks Supporting Drone Usage

The establishment of supportive regulatory frameworks is a crucial driver for the Drone Wind Turbine Blade Inspection Market. Governments and aviation authorities are increasingly recognizing the benefits of drone technology in various sectors, including energy. Regulations that facilitate the safe and efficient use of drones for inspections are being developed and refined. For instance, streamlined processes for obtaining flight permissions and guidelines for drone operations in proximity to wind farms are becoming more common. This regulatory support not only encourages investment in drone technology but also fosters confidence among operators in utilizing drones for inspections. As regulations continue to evolve, they are expected to further stimulate the growth of the Drone Wind Turbine Blade Inspection Market.

Technological Innovations in Drone Capabilities

Technological innovations play a pivotal role in shaping the Drone Wind Turbine Blade Inspection Market. Advances in drone technology, such as improved imaging systems, enhanced battery life, and autonomous flight capabilities, are transforming inspection processes. High-resolution cameras and thermal imaging sensors enable detailed assessments of blade conditions, identifying issues that may not be visible to the naked eye. Furthermore, the development of artificial intelligence algorithms for data analysis allows for quicker decision-making regarding maintenance needs. As these technologies continue to evolve, they are likely to enhance the effectiveness and reliability of drone inspections, thereby driving growth in the Drone Wind Turbine Blade Inspection Market.