Rising Demand for Real-Time Data

The modern manufacturing-execution-system market is experiencing a notable surge in demand for real-time data analytics. This trend is driven by the need for manufacturers to enhance operational efficiency and decision-making processes. In the GCC region, companies are increasingly adopting systems that provide instantaneous insights into production metrics, inventory levels, and equipment performance. According to recent data, the market for real-time data solutions is projected to grow at a CAGR of 15% over the next five years. This growth is indicative of a broader shift towards data-driven manufacturing practices, where timely information is crucial for maintaining competitive advantage. As manufacturers seek to optimize their operations, the integration of real-time data capabilities into modern manufacturing-execution-systems becomes essential.

Government Initiatives and Support

Government initiatives in the GCC region are playing a pivotal role in shaping the modern manufacturing-execution-system market. Various national strategies aim to diversify economies and reduce reliance on oil, leading to increased investments in advanced manufacturing technologies. For instance, initiatives such as Saudi Vision 2030 and UAE Vision 2021 emphasize the importance of digital transformation in manufacturing. These programs often include financial incentives, grants, and support for technology adoption, which encourage manufacturers to implement modern manufacturing-execution-systems. As a result, the market is likely to witness accelerated growth, with an expected increase in system adoption rates by approximately 20% over the next few years. This government backing not only fosters innovation but also enhances the overall competitiveness of the manufacturing sector.

Focus on Quality Control and Compliance

Quality control and compliance are becoming increasingly critical in the modern manufacturing-execution-system market. Manufacturers in the GCC are under pressure to meet stringent regulatory standards and customer expectations. The implementation of modern manufacturing-execution-systems allows for enhanced tracking and monitoring of production processes, ensuring that products meet quality specifications. This focus on quality is reflected in the market, where systems that offer robust compliance features are gaining traction. Recent studies indicate that approximately 30% of manufacturers are prioritizing investments in quality management systems as part of their overall strategy. This trend underscores the importance of integrating quality control measures within manufacturing processes, thereby driving the demand for advanced execution systems that facilitate compliance and enhance product reliability.

Growing Emphasis on Supply Chain Optimization

Supply chain optimization is emerging as a key driver in the modern manufacturing-execution-system market. Manufacturers in the GCC are increasingly recognizing the importance of efficient supply chain management to enhance overall operational performance. The integration of modern manufacturing-execution-systems allows for better visibility and control over supply chain activities, facilitating timely decision-making and resource allocation. Recent data indicates that companies focusing on supply chain optimization can achieve cost reductions of up to 15%. This growing emphasis on optimizing supply chains is likely to propel the adoption of advanced execution systems, as manufacturers seek to improve responsiveness and agility in their operations. Consequently, the modern manufacturing-execution-system market is expected to benefit from this trend, with increased investments in technologies that support supply chain efficiency.

Increased Investment in Automation Technologies

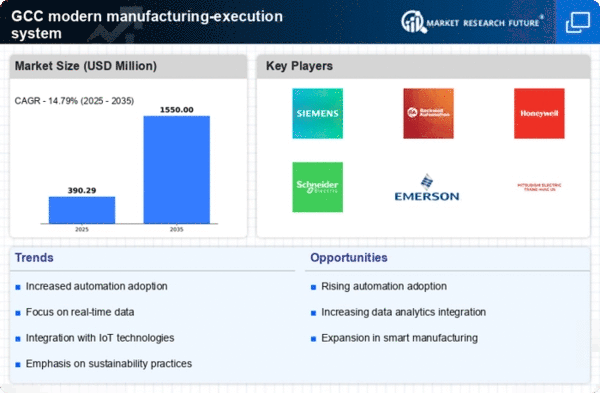

The modern manufacturing-execution-system market is witnessing a significant increase in investment in automation technologies. As manufacturers in the GCC strive to improve productivity and reduce operational costs, the adoption of automated solutions is becoming a priority. Automation not only streamlines production processes but also minimizes human error, leading to higher efficiency. Recent market analysis suggests that investments in automation technologies are expected to grow by 25% over the next five years. This trend is indicative of a broader shift towards smart manufacturing, where modern manufacturing-execution-systems play a crucial role in integrating various automated processes. The potential for enhanced productivity and cost savings is driving manufacturers to embrace these technologies, thereby propelling the market forward.