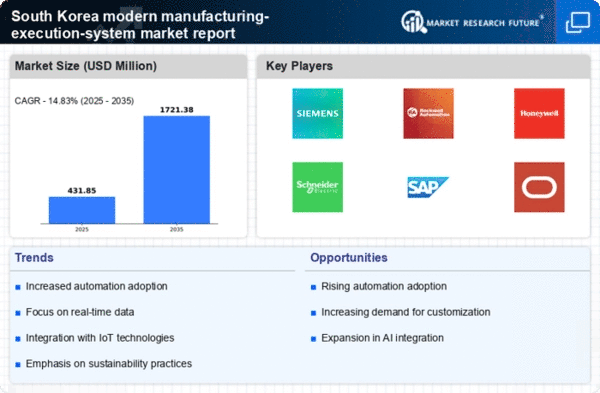

The modern manufacturing-execution-system market in South Korea is characterized by a dynamic competitive landscape, driven by rapid technological advancements and increasing demand for operational efficiency. Key players such as Siemens (DE), Rockwell Automation (US), and Honeywell (US) are at the forefront, each adopting distinct strategies to enhance their market presence. Siemens (DE) focuses on digital transformation and innovation, leveraging its expertise in automation and data analytics to provide comprehensive solutions. Rockwell Automation (US) emphasizes partnerships and collaborations, particularly in integrating AI and IoT technologies into its offerings. Honeywell (US), on the other hand, is concentrating on sustainability initiatives, aligning its product development with environmental goals, which resonates well with the growing emphasis on green manufacturing practices. Collectively, these strategies not only enhance their competitive positioning but also contribute to a more integrated and technologically advanced market environment.

In terms of business tactics, companies are increasingly localizing manufacturing to reduce lead times and optimize supply chains. This approach appears to be a response to the complexities of global logistics and the need for agility in production. The market structure is moderately fragmented, with several players vying for dominance, yet the influence of major corporations remains substantial. Their ability to innovate and adapt to changing market demands shapes the competitive dynamics significantly.

In October 2025, Siemens (DE) announced a strategic partnership with a leading South Korean tech firm to develop advanced AI-driven manufacturing solutions. This collaboration is poised to enhance Siemens' capabilities in predictive maintenance and real-time data analytics, thereby improving operational efficiency for manufacturers. The strategic importance of this move lies in Siemens' commitment to staying ahead in the digital transformation race, which is crucial for maintaining competitive advantage in the modern manufacturing landscape.

In September 2025, Rockwell Automation (US) launched a new suite of software solutions aimed at enhancing supply chain visibility and operational resilience. This initiative is particularly relevant as manufacturers seek to mitigate risks associated with supply chain disruptions. By providing tools that enable real-time monitoring and analytics, Rockwell Automation positions itself as a leader in facilitating agile manufacturing processes, which is increasingly vital in today's fast-paced market.

In August 2025, Honeywell (US) unveiled its latest sustainability-focused manufacturing platform, designed to help companies reduce their carbon footprint while optimizing production efficiency. This platform integrates advanced analytics and IoT capabilities, allowing manufacturers to track and manage their environmental impact effectively. The strategic significance of this development underscores Honeywell's commitment to sustainability, which is becoming a key differentiator in the competitive landscape.

As of November 2025, the most pressing trends shaping competition in the modern manufacturing-execution-system market include digitalization, sustainability, and the integration of AI technologies. Strategic alliances are increasingly pivotal, enabling companies to pool resources and expertise to drive innovation. Looking ahead, competitive differentiation is likely to evolve from traditional price-based competition to a focus on technological innovation, supply chain reliability, and sustainable practices. This shift indicates a broader transformation in the market, where companies that prioritize these elements may gain a significant edge.