Expansion of Oil and Gas Sector

The ongoing expansion of the oil and gas sector serves as a crucial driver for the Hazardous Location Connectors Industry Market. As exploration and production activities intensify, particularly in offshore and remote locations, the need for specialized connectors that can operate in hazardous conditions becomes paramount. The oil and gas industry is expected to invest heavily in infrastructure, which includes the installation of connectors that comply with safety regulations. This investment is likely to bolster the market, with projections indicating a potential increase in demand for hazardous location connectors by approximately 8% annually. Such growth underscores the importance of reliable connectors in ensuring the safety and efficiency of operations in this high-risk sector.

Increased Industrial Automation

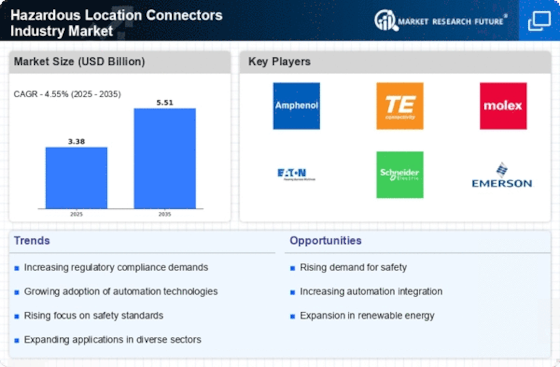

The rise of industrial automation is a pivotal driver for the Hazardous Location Connectors Industry Market. As industries increasingly adopt automated systems, the demand for reliable and safe electrical connections in hazardous environments escalates. Automation technologies, such as robotics and IoT devices, require connectors that can withstand extreme conditions while ensuring operational safety. The market for hazardous location connectors is projected to grow significantly, with estimates suggesting a compound annual growth rate of around 6% over the next few years. This growth is largely attributed to the need for connectors that meet stringent safety standards in sectors like oil and gas, chemicals, and mining, where the risk of explosions and fires is prevalent.

Growing Focus on Safety Standards

A growing focus on safety standards is significantly influencing the Hazardous Location Connectors Industry Market. Regulatory bodies are continuously updating safety regulations to mitigate risks associated with hazardous environments. This trend compels manufacturers to innovate and produce connectors that not only meet but exceed these safety requirements. The market is witnessing a shift towards connectors that are certified for use in explosive atmospheres, which is essential for industries such as pharmaceuticals and food processing. As companies strive to comply with these evolving standards, the demand for high-quality hazardous location connectors is expected to rise, potentially leading to a market growth rate of around 5% in the coming years.

Rising Demand from Renewable Energy Sector

The rising demand from the renewable energy sector is emerging as a significant driver for the Hazardous Location Connectors Industry Market. As the world shifts towards sustainable energy sources, the installation of renewable energy systems, such as wind and solar farms, necessitates the use of connectors that can withstand harsh environmental conditions. These systems often operate in remote and hazardous locations, where reliable electrical connections are critical. The market for hazardous location connectors is expected to benefit from this trend, with projections indicating a potential growth rate of around 6% as renewable energy projects proliferate. This shift not only supports environmental goals but also highlights the importance of safety in the deployment of new energy technologies.

Technological Innovations in Connector Design

Technological innovations in connector design are driving advancements in the Hazardous Location Connectors Industry Market. Manufacturers are increasingly developing connectors that incorporate advanced materials and designs to enhance durability and performance in extreme conditions. Innovations such as modular connectors and smart connectors that provide real-time monitoring capabilities are gaining traction. These advancements not only improve safety but also reduce maintenance costs and downtime for industries operating in hazardous locations. The market is likely to see a surge in demand for these innovative solutions, with estimates suggesting a growth rate of approximately 7% as industries seek to leverage technology for improved operational efficiency.