Growing Demand from Aerospace Sector

The aerospace sector is a significant driver for the High-Purity Aluminium Powder Market, as the demand for lightweight and high-strength materials continues to rise. High-purity aluminium powder is essential for producing components that require exceptional mechanical properties and corrosion resistance. The increasing focus on fuel efficiency and performance in aircraft design has led manufacturers to seek advanced materials, thereby propelling the demand for high-purity aluminium powders. Recent data suggests that the aerospace industry is projected to grow at a rate of approximately 4% annually, further boosting the market for high-purity aluminium powders. This trend indicates a robust future for the industry, as aerospace applications increasingly rely on these specialized materials to meet stringent performance criteria.

Diverse Applications Across Industries

The versatility of high-purity aluminium powder is a key driver for the High-Purity Aluminium Powder Market, as it finds applications across various sectors. From aerospace and automotive to electronics and pharmaceuticals, the demand for high-purity aluminium powder is expanding. In the automotive industry, for instance, the need for lightweight materials to improve fuel efficiency is driving the adoption of high-purity aluminium powders in manufacturing processes. Additionally, the electronics sector utilizes these powders for producing conductive materials and components. Recent estimates suggest that the market for high-purity aluminium powder could reach USD 1 billion by 2027, reflecting its growing importance across diverse applications. This broad applicability not only supports market growth but also encourages ongoing research and development efforts.

Technological Advancements in Production

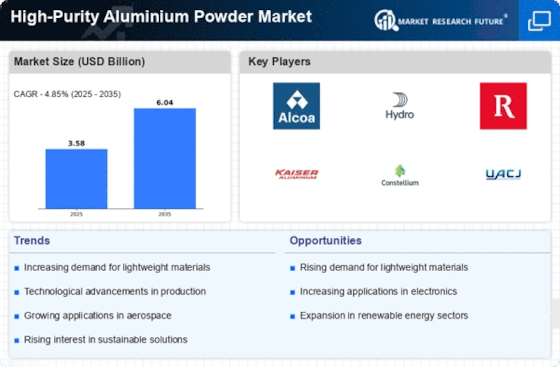

The High-Purity Aluminium Powder Market is experiencing a surge in technological advancements that enhance production efficiency and product quality. Innovations in atomization techniques, such as gas atomization and water atomization, have led to the creation of finer and more uniform powder particles. This is crucial for applications in aerospace and electronics, where precision is paramount. Furthermore, advancements in purification processes ensure that the aluminium powder meets stringent quality standards, which is increasingly demanded by manufacturers. As a result, the market is likely to witness a rise in demand for high-purity products, with projections indicating a compound annual growth rate of over 5% in the coming years. These technological improvements not only optimize production but also reduce waste, aligning with the industry's sustainability goals.

Sustainability and Environmental Regulations

The High-Purity Aluminium Powder Market is significantly influenced by the growing emphasis on sustainability and environmental regulations. As industries face increasing pressure to reduce their carbon footprint, the demand for eco-friendly materials is on the rise. High-purity aluminium powder, being recyclable and energy-efficient in production, aligns well with these sustainability goals. Regulatory frameworks are evolving, pushing manufacturers to adopt greener practices, which in turn drives the demand for high-purity aluminium powders. Market analysis indicates that companies focusing on sustainable production methods are likely to gain a competitive edge, as consumers and industries alike prioritize environmentally responsible sourcing. This shift not only enhances the market's growth potential but also encourages innovation in production techniques.

Rising Investment in Research and Development

Investment in research and development is a crucial driver for the High-Purity Aluminium Powder Market, as companies strive to innovate and improve product offerings. Increased funding for R&D initiatives allows manufacturers to explore new applications and enhance the properties of high-purity aluminium powders. This focus on innovation is particularly evident in sectors such as aerospace and electronics, where the demand for advanced materials is ever-increasing. Furthermore, collaborations between industry players and research institutions are fostering the development of novel production techniques and applications. Market forecasts indicate that R&D investments in this sector could lead to a 6% increase in market size over the next five years, highlighting the importance of continuous innovation in maintaining competitiveness and meeting evolving customer needs.